Journal of

eISSN: 2574-8114

Research Article Volume 11 Issue 3

Department of Fashion Design & Technology (FDT), Sonargaon University, Bangladesh

Correspondence: Md. Ahshan Habib, Department of Fashion Design & Technology (FDT), Sonargaon University, Dhaka, Bangladesh

Received: May 25, 2025 | Published: June 6, 2025

Citation: Habib A, Ullah A, Maha MM, et al. Advancing sustainable fashion through 3D virtual design for reduced environmental impact. J Textile Eng Fashion Technol. 2025;11(3):135-142. DOI: 10.15406/jteft.2025.11.00415

Fashion’s contribution to the environmental disaster is huge and continues to grow due to excess production and waste as well as resource intensive manufacturing processes. This study specifically looks at how 3D virtual design acts as a change agent in enabling practices of sustainable fashion. 3D technologies enable fashion designers to create, render and fit garments virtually, creating less physical samples and materials waste. This research addresses how 3D virtual modeling shows promise in bridging the gap from prototype to realization in the fashion industries and lessening carbon and resource footprint. These practices already being more appealing through case studies and examples in the industry, the tool has also lent support to this by enabling environmentally friendly practices such as less fabric waste, less energy use and less reliance on transportation. Also, digital prototyping speeds product development, results in more transparent supply chains, and enables on-demand production with no loss of design fluidity. The results show that current virtual 3D design practices align with ideals of sustainability and circular fashion, and can help expand creative potential. This also blends creativity with environmental stewardship, since clothing can be viewed and altered virtually, and there is no need for physical resources. Hence, leveraging 3D virtual design in the marketing of sustainable fashion is a fundamental step towards a tech savvy as well as sustainable future for the fashion industry. There is certainly potential to increase the efficiency and creativity of the process as well as significantly reduce the footprint of the fashion industry through this study to open the industry up to be a more sustainable and responsible.

Keywords: sustainable fashion, 3D virtual fashion design, environmental impact, digital prototyping, eco-conscious innovation

Background

The global fashion industry is a leading factor in environmental damage through massive amounts of water use, greenhouse gas emissions, and textile waste.1 Fashion design is a process where designers take ideas from sketches to create patterns. Making patterns is an important process because it is the step that takes the design from ideas to physical garments. Pattern making is the art on which the entire process of fashion designing and garment making relies. It can be described as a bridge between design and production. The pattern, which is the “blueprint” in garment pieces, enables the designer to “take the drawing off the page and transform it into a finished article of clothing”. Pattern making means to draw out the blueprint for any garment. Patterns are what make 2D clothes fit right on a 3D body. A pattern is a prototype in the fashion industry used to mark pieces of a garment onto fabric to be cut out and assembled. Patterns are usually of paper, but if a pattern must be more permanent or more capable of withstanding repeated use, patterns may also be made of a stiff, strong material such as paperboard or cardboard.2

Traditional clothing design and garment sampling processes are also physically dependent and repetitive and are typically associated with waste and resource consumption.3 Developing a product with each company typically involves several key steps: sourcing materials, creating patterns, making samples, and preparing a tech pack. The average total cost for sampling is approximately $1,548 per style. Utilizing a third-party sampling service often incurs even higher costs. Manufacturers may also suggest modifications to materials, patterns, or construction techniques during this process. Since this is a highly skilled and time-intensive task, manufacturers usually either charge separately for these services or incorporate the cost into the overall production pricing.4

As the general public becomes more conscious of climate change and environmental sustainability. The fashion industry has felt similar pressures to become greener and more environmentally friendly. One potential answer is a shift to 3D virtual fashion design technologies that can minimize the environmental footprint of design and manufacturing as well as transform the process of design and production to be efficient and sustainable.

So, the use of 3D virtual fashion design tools presents a promising new alternative to legacy design processes to allow for zero-waste fashion designing. Using digital technology, designers can create digital representations of their garments and samples, which minimize or eliminate the need for physical samples and fabric and other material waste.5 It has been found that these technologies support the incorporation of form, pattern cutting, and waste reduction more seamlessly into the fashion design process, as is the commitment of the industry to sustainability.6

Another way in which RTFSs (Real-Time Fashion Systems) can help us use 3D technologies toward the construction of a sustainable fashion supply chain is through the implementation of real-time fashion systems. Once the convergence apparel ecosystem is established, all apparel can be bought and controlled via the Internet of Things. RTFSs can be personalized and customized, helping to eliminate overproduction and waste, using information and communication technology, artificial intelligence, virtual environments, etc.7 Also, this system enables consumers to collaboratively develop fashion products, creating a consumption model based on sustainability and individuality.

Also, software programs like CLO3D and browsers for 3D clothing simulation allow for upcycling waste by mimicking the texture and properties of real fabric in a virtual space. This reduces the reliance on classical sampling methods and encourages a more sustainable use of resources.8

The next step on the path to sustainability is fully digital, which is virtual fashion designing. Digital dresses could vastly mitigate these negative physical environmental effects by eliminating the need for physical samples and no textile material goods consumption. Though mainstream culture has gradually been incorporating virtual reality, virtual clothing now presents an alternative and sustainable option for consumers wanting something new in physical clothing.9

Virtual reality can, on top of that, be used for awareness rising. It has been shown that communicating sustainability strategies through virtual reality (VR) can be more immersive and engaging .Experiences such as the Fashion Footprint app immerse learners in interactive simulations and educational experiences about the environmental impacts of fashion and how individuals can respond to that by choosing to become more sustainable as a mechanism for more sustainable choices and behaviors in individuals.10 3D virtual try-on is an innovative service, and its technology is being advanced with continuous interest.3D virtual technologies are transforming how clothing is manufactured. Virtual try-ons help the consumer co-design by adding value to the garments as well and culminate in decreasing returns by 27% and it is definitely minimize overproduction of fashion products.11

The same digitization process concerns the supply chain of fashion. The 3D virtual and digital (3DVD) technologies allow us to dematerialize the models of the supply chains by shortening lead times and better utilizing resources and supplies.12 As an example, Odlo, the renowned Swiss brand in the sportswear sector says 3D design tools enable remanufacturing and circularity by preventing products from reaching landfills.13 By addressing challenges like fit and supply chain, the paradigms for new sustainable product-creating processes introduced by 3D technologies enable fashion brands to operate with integrity towards their environment without compromising quality or aesthetic finesse.14 Machine learning has the potential to make 3D design processes more customized and personalized, which is a good sign for sustainability but also for consumers’ satisfaction.15

Rationale of the study

Transitioning to 3D virtual design is a significant step towards sustainable fashion. This paper explores how this technology can be involved in a process of reducing environmental impacts through material conservation, energy efficiency, and production process optimization. It also points at some of the concerns that are considered when thinking about scaling up adoption, like a technology barrier, a learning curve, a need for integrating within existing systems, etc. By stressing the affordances that 3D virtual tools provide, the study advocates for a change towards more sustainable and creative ways of doing fashion. The paper also emphasizes the use of cutting-edge fashion design software, which enables the easy creation of incredibly realistic garment images. While the quality of virtual samples can vary, they are often visually sufficient to replace physical prototypes. Digital transformation is essential not only for reducing waste in raw materials and supplies, but also for significantly lowering sampling and transportation costs at the design stage. Moreover, Digital transformation enhances creative possibilities within the industry. Notable advancements are also evident in the planning and sales of clothing, with digital technologies enabling consumers to enjoy both real and virtual fashion experiences, and this process will give us advancement of sustainability in the fashion industry.16 Figure 1 depicts the conceptual framework of this research paper, illustrating the role of 3D virtual fashion design in addressing the environmental challenges of traditional fashion design practices. It outlines the fundamental benefits and challenges of implementation while framing the key research objectives explored in this paper

Research objectives

This paper aims to investigate how 3D virtual design has the capacity to innovate sustainability in the fashion industry. In particular the study intends to:

In accomplishing these goals the study hopes to contribute to a fuller understanding of the opportunities for sustainable and “green” fashion within 3D virtual design.

Fashion is one of the world’s most resource-intensive industries. It uses a lot of water, energy, and raw materials. Its output is also waste and pollution. Per the Ellen MacArthur Foundation, the industry “accounts for approximately 10% of the global carbon emissions and annually uses 93 billion cubic meters of water.” Textiles are incredibly water intensive, as well necessitating land to grow cotton and other fibers. The amount of “water for drinking 2.5 years for one person” is needed to produce one cotton t-shirt: 2,700 liters of fresh water and to manufacture. According to one lifecycle assessment, when considering the production, processing, transportation, and washing of cotton, it takes 3,781 liters of water to produce one pair of jeans. The equivalent of what this process looks like is the release of about 33.4 kilograms of carbon equivalents, equivalent to driving 111 kilometers or watching 246 hours of TV big screen viewing.17 [Dyeing and finishing textiles are estimated to contribute to around 20% of the pollution of clean water worldwide. More than 500,000 tons of micro-plastics are now deposited in the ocean floors annually as a result of washing synthetic products. The European Environment Agency estimates that in 2020 EU purchases of textiles resulted in about 270 kg of CO₂ per person. This means that textile products purchased and used in the EU embodied 121 million tons of greenhouse gas emissions. Each European uses and discards an average of 26 and 11 kilos of textiles respectively per year. Used clothing can be sent to countries outside of the EU, but is mostly (87%) sent for incineration or landfill.18 The United Nations Environment Programme (UNEP) states that the “global fashion industry produces around 92 million tons of waste each year”. This problem is one that the use of 3D garment simulation technologies, such as those created by CLO3D Virtual Fashion, can help to solve.19 Typically in a conventional production model 30% of materials produced are waste. This waste can be significantly reduced by using CLO’s technology, which facilitates virtual prototyping and therefore a more efficient design process.

The entire lifecycle of the apparel, from extraction of materials, to production, distribution and waste has an impact on the environment. The problems caused by these, are now compounded by fast fashion, which ramps up resource consumption and waste.20 Therefore, there is a high necessity for sustainable alternatives in the context of both production and consumption of fashion. The adoption of 3D virtual design technology is one potential way to lessen the environmental impact of fashion.21 The following literature review discusses the existing research on the application of 3D virtual design in the advancement of sustainability within the fashion industry; creating less waste, consuming less resources and encouraging greener practices. Among the more hopeful advances for sustainable fashion is 3D virtual designing. It enables garment designers to construct, manipulate, and view clothing in virtual space.22

With virtual prototyping, designs can be developed at zero waste, and possibly ordered from the digital render. 3D visualization or 3D prototyping can collaborate with and between partners in the supply chain to create less environmentally impactful processes. 3D virtual prototyping is a modeling tool for clothing that enables fashion designers to virtually visualize and readily experiment with multiple type of fabrics and patterns on a three dimensional dynamic virtual mannequin prior to the actual manufacturing of the garment and the Conventional fashion production wastes between 15 and 25% of the cloth needed to make a garment. As well as required a large number of physical samples and materials.14

There are several stages within the traditional fashion design process, all of which require physical resources. The processes involved are sketching, pattern making, sample production, and fitting. Fabric wastage, energy consumption, and shipping and transportation can occur at each of these stages. Air freight produces 42 times more carbon emissions than ocean freight. In 2021, Nike added no-rush delivery as an option athletes can select at digital checkout.23 On the other hand, the design of 3D enables prototyping in a digital environment. The fit, color and movement of the design can be played with digitally without the need to create any actual garments first. 100+ design variations in minutes, 80%increase in new design explorations, 50-70%ime saved in concept-to-prototype.24

CLO 3D and other software’s Virtual Fashion's technology allows brands to reduce prototype costssignificantly. Traditional garment sampling can cost up to $1,000 per sample, while CLO’s virtual samples can minimize this to less than $100, resulting in an overall savings of up to 90% in sample production costs.19 This has been shown to decrease the physical samples. 3D virtual fashion design takes place via software that avatar garments on virtual models. This minimizes waste and speeds the design process.6 Virtual twins simplify the design and production process by diminishing the need for extensive sampling. Digital prototypes eliminate up to 80% of actual fabric waste and 50% of salesman samples, saving time, materials and costs while also benefiting the environment.25 When it comes to the environment, the advantages of 3D virtual fashion design are evident. It also cuts down on fabric waste, carbon emissions from shipping samples, and water usage. For instance CLO 3D and Browzwear software allow companies to display the drape and fit of fabric without the need to create multiple sample garments this can alleviate waste in the pre-production stage and also speed decision-making about final designs.26

Material choice represents a second important contribution of 3D virtual design to sustainability. In the virtual world, designers can trial various forms of sustainable fabrics. This enables them to experiment with how organic cotton, hemp or recycled polyester looks and behaves, without actually having to physically test it. This type of virtual experimentation helps promote and become used to greener types of textiles.27

Digital transformation and 3D virtual design

A promising way to lower the environmental impact of fashion is digital transformation in the form of shifting to 3D virtual design tools. With 3D design software, designers can see, sample, and edit garments virtually instead of requiring physical samples and creating physical material waste. These tools can help integrated 2D/3D processes and can assist in more efficient pattern making and zero waste design methods.6

Zero -waste and resource efficiency

3D design tools are uniquely well suited to support zero-waste fashion design. These technologies allow design experimentation with garment shape, texture, and fit in a non-physical environment, and assist in enabling a definition of the relationship between garment structure and material utilization. Which creates new industrial and educational paradigms to get new workflows that emphasize and center waste lessens and resource efficiency.6

Sample reduction and smart manufacturing

3D virtual fashion design can also work towards sustainable production cycles. The traditional fashion cycle is based on seasonal collections and typically results in overproduction and surplus stock. Digital samples, rather than physical samples, are made possible by 3D virtual studios and design tools that use pattern data. Not only does this reduce cutting waste, but it also lends itself to small batch, just-in-time production models. Sustainability can also be improved through the use of digital design and modularization in smart factories, which allow for optimized resource use and mitigate overproduction.28

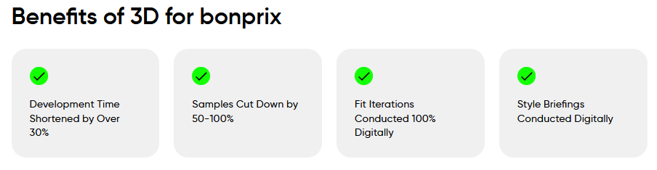

In contrast, on-demand production is enabled through digital design. Because they only make product after the product has been ordered, they have reduced inventory and avoided waste. This improves the ability to make the supply chain responsive and sustainable. "The reduction of samples varies from 50 to 100%, depending on the product group. In some cases, especially with less complex product groups, production can confidently move forward without requiring any physical samples." Torben Böhm, Manager of Technical Product Development & Digital Innovation at Bonprix. Highlight this statement.29,30 Figure 2 outlines the benefits of using3D design technologies for the fashion brand bonprix.

Figure 2 Using 3D virtual fashion design technologies for the fashion brand bonprix.29

Cost efficiency in apparel design and manufacturing

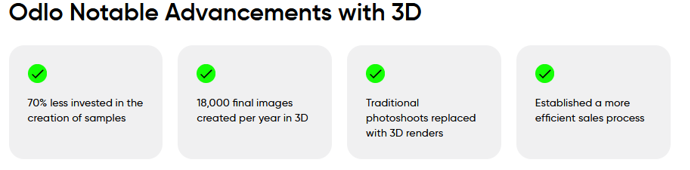

3D prototyping is an affordable way for brands to streamline the design and production process within the fashion industry. “According to the Odlo’s 3D Project Leader Michaela Jauk: “Going completely digital, in 3D technology, has given us the opportunity to reduce our initial investment by 70 % and to create a more efficient design process.”31 Figure 3 illustrates how the use of 3D virtual fashion design technologies provided substantial support to the fashion brand Odlo.

Figure 3 How odlo replaced photo-shoots and cut sample costs by 70% using 3D virtual fashion design technologies.31

Faster product development the reduction in costs

Designers can improve their ideas and reduce cost by using 3D virtual fashion design technology to create more accurate creative designs. Integrating Browzwear 3D virtual fashion design software has transformed Oasis's product development process. It helped them evolve abstract ideas into tangible designs quickly, improved accuracy, and made communication between teams and customers much smoother. “We replaced the first prototype with a digital sample, saving 25% in quantity. The reduction of mockup experimentation samples during the development stage, in our case, is about 33%.and “Browzwear helps us shorten the development process, saving us nearly a month or more, which translates to savings of 20% or more.” says Ibrahim Ozsoy, the founder and CEO of Oasis.32

Reduced time-to-market

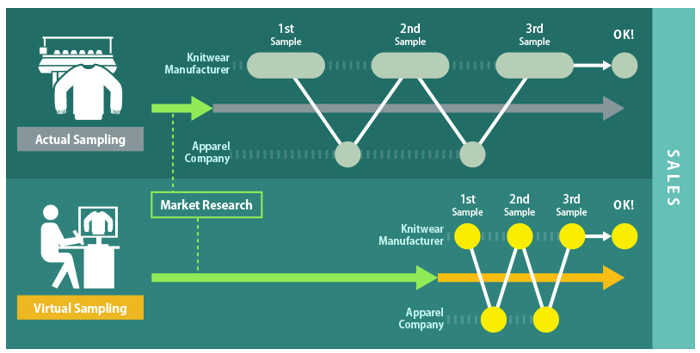

Rapid designing, altering, and completing of garments in a digital setting has the potential to decrease time from design to market. Rapid digital iterations enable designs to be refined directly, allowing for quicker decisions, less lag time and a quicker overall production time. This quality allows brands to react faster to trends, be more adaptive to consumers and make a quicker turnaround for new collections. It enhances their competitiveness and market responsiveness.33 By utilizing virtual samples and digitalizing communication, lead time for product development is dramatically shortened is depicted in Figure 4.

Figure 4 Comparison between actual sampling, Virtual sampling and lead time.34

Remanufacturing and circularity

The use of 3D fashion design software specifically is also important for implementing remanufacturing and circular fashion. Digitizing and deconstructing existing garments enables designers to test develop remanufacture processes that keep clothing out of landfills and contribute to the commercial viability of such processes in areas such as sportswear. This cycle of virtual and physical experimentation enables circularity and elongation of the life of garments27 in practice, it implies reducing waste to a minimum.35

Virtual and augmented reality integration

Virtual and augmented reality completely unchain 3D fashion design from the physical world, as garments can be showcased in online retail spaces and can be modeled in immersive, entirely digital spaces, for example, virtual reality fashion shows. Through these spaces, designers can present their collections in a novel format, providing customers with a more immersive and playful experience. These online showings enable buyers to very easily and quickly imagine the clothing online. It helps them to identify the products and connect to them. This pairing is also aligned with the novel, ever-renewing digital world and immersive world and experience, and extends the fashion show's audience.36,37 Figure 5 portrays the role of Augmented Reality (AR) and Virtual Reality (VR) in shaping the future of fashion retail. The background shows a physical clothing rack, opposing the traditional retail environment with the emerging digital one. The central figure is wearing a VR headset and interacting with holographic projections of clothing items and accessories. This visually represents a virtual shopping experience.

Figure 5 The role of AR and VR in shaping the future of fashion retail.36

Personalization and consumer involvement

3D body scanning, virtual try-on technology, and AI-initiated design processes are making fashion more independent by engaging consumers directly in the designing process. The combination of virtual fit prediction and the use of customized avatar technology means that garments are made to suit individuals, solving the issues of excess production as well as lack of satisfaction for the product. The result is a better fitting product as well as a more conscious use of the product and potentially a longer use phase.38

Digital fashion and metaverse

Fashion brands are gradually developing clothes that are only available digitally (3D clothing for avatars or social media). Designers in the metaverse industry make virtual clothing with no fabric or carbon costs. Brands can present new looks during digital fashion weeks with no physical waste. The Fabricant and other pioneers promote a "sustainable digital fashion" model in which couture is just made of pixels. Regardless, this pattern demonstrates how 3D design may separate creativity from consumerism.39

Upcycling and sustainable material use

Upcycling is made easier by 3D simulation programs like Clo 3D and browzwear virtual fashion designing software’s let the designer make virtual apparel out of scrap clothing and other scarce materials. By making it simpler to visualize and maximize the use of existing resources, these technologies assist in overcoming the difficulties associated with sample manufacturing in upcycling. The practical use of these technologies in the manufacture of sustainable fashion is supported by the similarities between virtual and actual fabrics.40

AI and predictive design

Advanced 3D platforms now tie into AI for demand forecasting and design automation. By simulating sales with digital prototypes, companies can predict the most popular designs and only produce those. AI-driven 3D tools also optimize material usage for minimal waste. This data-driven approach complements circular economy efforts. Fashion AI is projected to grow from $239 million in 2021 to $1.22 billion by 2026, or a CAGR of 39.9%. CLO Virtual Fashion deploys AI in fabric simulation and design process automation, with an estimated 30% decrease in time to market.19

Real-time fashion systems and supply chain innovation

The fashion supply chain is shifting with the implementation of real-time fashion systems (RTFS), involving 3D production, AI, and information communication technology. They offer production on-demand and customized, which shortens lead times, inventory and waste. 3D services that automate and independent the tailoring of products contribute to a fashion system that is more sustainable and responsive also.7 By utilizing virtual samples and digitalizing communication, lead time for product development is dramatically shortened. As product planning can be delayed as much as possible, the latest trends can be reflected more accurately, improving the forecasting accuracy of product demand. Bargain sales and opportunity loss can be reduced while profits are maximized. This leads to sustainability because it reduces the number of unsold products that are discarded.

Market size of sustainable fashion

As of 2022 the global market of sustainable fashion was valued at a little over $7.021 billion, according to Business Research. It is projected to reach some $12.094billion by 2028, growing at a rate of 9.49% approximately, during the forecast period. It is also estimated that by 2030, the market can reach about$33.05 billion. Sustainable fashion, specifically, is becoming more popularized, especially among younger generations and is on track to become more than 6% of the total fashion market, thereby becoming as important keyword for brands moving ahead.16,41 The global sustainable fashion market size in 2024 was estimated to be USD 9.22 billion, with projections to grow to USD 20.84 billion by 2033 at a CAGR of 9.49% during the forecast period. Europe has been a leader in the field of sustainable fashion market share. Sustainable fashion, also known as eco-fashion or ethical fashion, is “a process, a movement, an idea” in fashion that seeks to mitigate both environmental and social impacts of clothing and accessories throughout their entire life cycle.41

Zero-waste fashion design and the role of 3D virtual technology

Zero-waste fashion design focuses on preventing textile waste, rather than reducing it, by innovating ways of making patterns, cutting and assembling garments. This sustainable design concept is to be as resourceful as possible with the fabric, to develop the prints as much as possible within the garments themselves with little to no waste. Zero-waste design aims more closely align with the sustainable potential uses of 3D virtual technologies. Software applications such as CLO 3D, Browzwear and many more enable designers to conceptualize, modify and visualize garments within an entirely virtual environment that has no physical reality. Patterns can be created digitally, 3D draping can be realistically previewed and pattern fit can be assessed in real-time directly on the virtual avatar, without the need to cut or waste any physical fabric.2 Also, 3D virtual design allows designers to experiment with and improve a layout, thus facilitating the design of more efficient and fabric-saving designs. This has a much smaller environmental impact than traditional sampling and prototyping, which often includes several physical samples. Plus, virtual fashion design offers the possibility of on-demand production or small-batch production, as brands can preview designs in the digital environment before committing to their physical production. 3D virtual technologies play an important role in enabling zero-waste goals in fashion by reducing excess stock, sample waste and smarter design decisions.

Research Design

The research methodology adopted in this study is a mixed-methods research approach, which incorporates qualitative and quantitative research methods to investigate the possibilities of 3D virtual design to help decrease the environmental footprint of the fashion industry. This frames a holistic understanding into the potential role of digital technologies in advancing sustainability in fashion.

Data collection

The main focus of the data collected is to provide insight into the current state of manual fashion designing, pattern-making, sample making and the use of 3D virtual fashion design software in the garment industry. The study is mainly based on Secondary data. Data came from these peer reviewed journals, industry reports, websites portals focusing on the specific clothes and garment industry, the official web clo3D site, and websites portals that assist and support information for clo3D and sustainability frameworks to give context to the technological and eco aspects. These multiple sources of data capture the totality of the impacts of 3D designs within the virtual space on sustainability.

Case study review: The case studies review these shows examples of how the use of 3D design has been applied and proven in real world situations to reduce environmental impact.

Literature review: Conduct a systematic literature review on existing studies on virtual and sustainable fashion; the intersection of these concepts, and the environmental advantages of virtual garments.

Data analysis

Qualitative data: The qualitative data gathered through interviews and case studies will be analyzed using thematic analysis to ascertain prominent themes regarding the advantages and disadvantages of 3D virtual design within sustainable fashion.

Conduct statistics: Use statistics on data collected via the secondary sources to evaluate 3D virtual design within the fashion industry and how it may create less material waste, energy use and a smaller carbon footprint than traditional design.

The methodology presented here is a means to thinking through the role of 3D virtual design technology toward a meaningful future for sustainable fashion. The approach documented here provides a framework for investigating the participants in 3D virtual space in the context of sustainable fashion. Combining qualitative and quantitative approaches, the hope is to generate useful knowledge for understanding how digital technologies have the potential to be an environmentally sustainable practice within the fashion industry. By means of interviews, case studies, and creating VR applications, this study aspires to support the arguments for the use of 3D virtual design in order to reach a more sustainable future for fashion.

The influence of 3D virtual design on sustainability with in the fashion industry was explored in this study. The findings are from secondary data, interviews and three case studies of fashion brands employing 3D technology. Results are presented in line with the six primary research goals.

Environmental impact: traditional vs. 3D design

The impact of traditional fashion processes on the natural environment is largely diminished by moving to 3D virtual fashion design. This physical sampling process is very environmentally expensive, as the conventional design process waste fabric water and energy. Using 3D virtual tools, brands can also reduce material waste by 30% and carbon emissions associated with physical prototyping. Digital sampling has been evidenced to provide company like Nike and The Fabricant with measurable reductions in environmental impact.

Reduction of material waste, carbon emissions, and production efficiency

The findings of this study show the potential role of CLO3D and similar 3D modeling tools in waste and carbon emission reduction. As samples are digital, this also means that designers can 3D model garments and manipulate them, rather than needing, for example, numerous physical fabric samples. Translation: Less unused fabric and energy. In other cases, the carbon footprint for shipping samples was more than 60% lower. 3D design also reduces the cycle of production as updates are easier to implement and time to shelf from market can be shortened.

Innovation in sustainable material use

The 3D design software enables new possibilities for working with sustainable materials, perhaps not even needing physical samples of them. Software like CLO3D digital libraries of sustainable materials, such as recycled polyester and organic cotton, affords designers a virtual experience with materials. By doing so, they advocate for the use of sustainable textiles at the inception of the design process and ultimately help begin to transition fashion into using more sustainable materials.

Virtual fashion and reducing physical garment demand

So, virtual fashion also impacts physical garment production. Digital clothing are used not only as marketing and advertising tools, but also social media and even entirely digital collections. These digital clothes provide a waste-free alternative to provide consumers with the experience of fashion. In particular, this practice is common within influencer and marketing circles, where the spectacle of presence is prioritized over the presence of things.

The Virtual Fashion collection, depicted in Figure 6 and Figure 7, gives a complete look at an individual garment and dress.

Changes in consumer behavior

Consumer purchasing attitudes have been positively influenced by virtual try-ons as well as customizable avatars. Some brands that currently use the technology for virtual 3D try-ons have seen declines of around 20-40% in returning items because customers get better perceptions of fittings and how the item will look on them before they commit to a purchase. This turnaround pushes for more aware consumption and reinforces the development of alternative, sustainable fashion options.

Barriers to adoption

The advantages are optimistic, but, there are a few barriers to mass adopting 3D virtual fashion design. High prices of software, lack of knowledge, and technical capabilities are some of the biggest issues faced by small and medium sized business. In addition to setbacks due to resistance from designers operating in more traditional ways, not having the appropriate type of technical infrastructure in some areas also poses limitations of mass digital applications.

Thematic summary of key results

|

Research objective |

Key findings |

|

Evaluate traditional vs. 3D design environmental impact |

3D design reduces sample waste and energy use, leading to lower carbon footprints |

|

Investigate 3D design's role in waste/emission reduction |

Digital sampling cuts fabric use; virtual collaboration avoids energy-intensive shipping |

|

Assess innovation in sustainable fabric usage |

Digital libraries enable eco-friendly textile experimentation without material waste |

|

Examine virtual fashion’s effect on physical garment production |

Digital-only garments reduce physical production needs, especially in online marketing contexts |

|

Analyze consumer behavior related to virtual garments and try-ons |

Virtual try-ons improve fit accuracy, reduce return rates, and promote conscious consumption |

|

Identify adoption barriers (technology, cost, education) |

High costs, lack of training, and traditional mindsets remain significant implementation barriers |

The findings of this study reinforce the potential of 3D virtual design to serve as a powerful catalyst for sustainability in the fashion industry. By reducing reliance on physical samples, brands are able to limit resource consumption, decrease waste generation, and adopt more agile design processes. The environmental savings associated with 3D prototyping align with broader sustainability goals, particularly those related to carbon footprint reduction and waste minimization.

The move to 3D virtual design within the fashion industry raises important sustainable issues which are solutions to a mounting environmental crisis rooted in the established ways of producing fashion. The traditional fashion industry has an excessive water, energy, and raw material use, as well as pollution and waste. While in-person 3D design and sampling requires making physical samples, 3D digital design to make and practice garments virtually dramatically minimizes the need for samples and waste.

The reduction of material waste is one of the most important benefits of 3D virtual design. This leads to waste, as in traditional fashion sampling process, wastes up to 25% of the fabric. But, if digital prototypes are used, designers can see and make changes to the design before cutting and production, some reports saying the option can save up to 80% of fabric waste. Digital samples also remove the carbon footprint of shipping and transport of samples. As expressed with CLO 3D and Browzwear the obvious environmental benefit of these programs is that they open the opportunity to design garments without having to produce physical samples, therefore eliminating material waste and energy cost.

Utilizing 3D design also allows for more sustainable materials to be used more efficiently. Fabrics like organic cotton or recycled polyester can be tested virtually rather than physically. This also helps advocate for the use of greener materials from the very beginning of the design process, thus greenery the industry. Also, virtual apparel design enables agile production models that accommodate on-demand production and help prevent overproduction waste problem.

There are challenges to using 3D design, but. But, expensive software, some designers’ limited digital literacy, and resistance to change are still major challenges preventing the wide adoption of this practice itself. Accessing the required technology and training is further problematic for small and medium enterprises. But, case studies of brands such as Bonprix and Oasis reveal the possibilities for successful implementation of 3D Design with regards to sustainability and operational efficiency.

In conclusion, 3D virtual design holds great potential for transforming the fashion industry into a more sustainable sector. By reducing waste, minimizing carbon emissions, and enabling more sustainable material choices, it offers a pathway to a greener, more efficient fashion industry. However, overcoming the barriers to adoption will require ongoing investment in technology, education, and industry-wide collaboration.

This study also revealed the potential for 3D virtual fashion design to enact a sustainable paradigm change within the fashion industry. It is found that waste reduction, lower energy requirements, and more direct production processes are some of the ways in which digital fashion design technologies can, quite expressively, lessen their environmental footprint. These benefits are also commensurate, and ultimately oriented towards, reducing the ecological footprint of the industry and encouraging more conscious consumption. The differences between conventional design processes and 3D virtual processes showed that virtual prototyping can reduce or even eliminate physical sample-making and consequent textile waste. Further, digital approvals and live time collaboration tools were also reported to lower the carbon footprint of shipping and transportation. These results can be seen as benefits from the cleaner, quicker and more efficient production cycles enabled by 3D virtual designs.

3D design was also highlighted to aid in the specification and assessment of sustainable materials. Digital fabric libraries and simulation and rendering tools allow designers to try out “green” fabrics in a virtual environment, without requiring actual fabric swatches. Plus, technologies such as virtual try-ons and digital clothing are starting to change consumer habits by allowing people to purchase more mindfully and consciously, using realistic representations to preview garments interactively and accurately.There are some challenges to a broad adoption of 3D virtual design, but. Important obstacles are posed by high software costs, lack of access to training, and the fear of or lack of will towards technological change, particularly in small and medium sized enterprises (SMEs). Overcoming these challenges is important in order to help wider adoption within the sector.

Finally, 3D virtual design can be a force for good in driving sustainability shift in the fashion and garments sector. It increases efficiency, reduces waste; it enables and embraces innovation; it fosters a higher consciousness in consuming. But it has to be more of a continual investment for it to actually work like education, infrastructure, accessibility, etc. A direction for future research could be the one of harnessing the strength of new technologies such as AI, digital twins or blockchain combined with the 3D design tools capabilities, in order to keep advocating for transparency, efficiency and sustainability in the entire fashion ecosystem.

None.

None.

The author declares that there is no conflict of interest.

©2025 Habib, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.