Journal of

eISSN: 2373-4345

Narative Review Volume 16 Issue 3

1Master and Specialist in Orthodontics, Private Clinic in Ribeirão Preto, Brazil

2PhD in Biomedical Engineering, MSc and Specialist in Orthodontics, Private Clinic in Uberlândia, Brazil

Correspondence: M.Sc Henrique Bacci, Faculty of Dentistry São Leopoldo Mandic, Av. Braz Olaia Acosta, 727, Sl 504, Jd Califórnia, Ribeirão Preto, São Paulo, Brazil

Received: August 01, 2025 | Published: September 16, 2025

Citation: Bacci H, Cunha DV. Revisiting 3D printing orientation in direct-printed aligners: a critical review. J Dent Health Oral Disord Ther. 2025;16(3):105-107. DOI: 10.15406/jdhodt.2025.16.00652

Background: Direct-Printed Aligners (DPAs) represent a recent advancement in the application of additive manufacturing in Dentistry. Among the technical factors affecting their clinical and laboratory performance, print orientation stands out for its influence on parameters such as geometric fidelity, mechanical strength, surface finish, and resin consumption. Despite this, oblique orientations remain widely adopted based on guidelines that are not always supported by scientific evidence, highlighting the need for a critical review of this practice.

Materials and methods: A narrative review of the scientific literature was conducted to investigate the impact of three-dimensional print orientation on critical performance variables in DPAs. This review was conducted through searches in the PubMed, ScienceDirect, Springer Link, Scopus, Web of Science, and Cochrane Library databases. The selection included studies published in the last five years, in English idiom, investigating light-curable resins applied to Dentistry, with emphasis on DPAs. Exclusion criteria: studies addressing non-resin materials, applications unrelated to Dentistry, or that did not describe print orientation parameters were excluded.

Results: The horizontal (0°) printing of DPAs has been associated with greater dimensional accuracy, reduced surface roughness, superior mechanical performance, and more efficient material usage. Although some studies have not identified statistically significant differences among various printing orientations, the evidence points to the technical and clinical advantages of the horizontal position. In contrast, inclined orientations for aligner printing, despite being recommended by manufacturers, have been linked to lower geometric fidelity, increased roughness, and poorer aesthetic appearance.

Keywords: Direct-printed aligners, additive manufacturing, print orientation, digital orthodontics

The incorporation of 3D printing into the fabrication of orthodontic aligners has brought significant transformations to the digital workflow of contemporary Orthodontics. In this constantly evolving landscape, it is natural that many technical parameters remain under consolidation, with manufacturer-recommended protocols serving as the most common starting point for experimental studies and clinical validations.1-3 Strict adherence to these protocols is understandable, particularly given the possibility that deviations may compromise mechanical properties, aesthetic aspects, and, most importantly, the clinical safety of the devices. However, among the various variables involved in the printing process, the orientation of the object during additive manufacturing stands out as one of the most critical factors, directly impacting the final quality of directly printed orthodontic aligners (DPAs). Paradoxically, it is precisely this parameter that appears to diverge most from the available scientific evidence, revealing a mismatch between commercial recommendations and laboratory data. The oblique orientation has been widely adopted as the standard, although there is no technical consensus regarding its superiority over horizontal or vertical positioning, as will be discussed in this work.

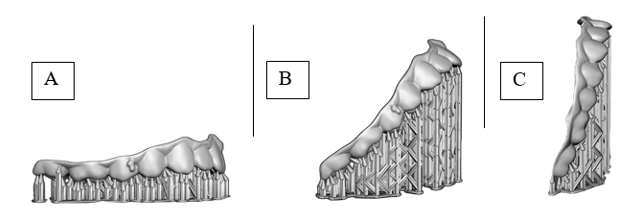

Several recent studies have investigated the impact of 3D print orientation on the quality of dental devices, as will be presented below. In the case of directly printed aligners (DPAs), three main angulations can be used in relation to the build platform: horizontal (0°), oblique (between 30° and 60°), and vertical (90°), as illustrated in Figure 1A–1C).

Figure 1 Angulations routinely used for printing direct-printed aligners (DPAs). A. Horizontal (0°); B. Oblique (30° to 60°); C. Vertical (90°) .

The dimensional accuracy of aligners printed in horizontal (0°), oblique (45°), and vertical (90°) orientations, associated with different ultraviolet post-curing times, has already been investigated.4 The results showed that such variations did not significantly impact overall dimensional precision, indicating that, under certain printing and post-processing conditions, orientation and curing time are not determining factors for accuracy.

Using PMMA resin samples printed at 0°, 45°, and 90°, one study5 observed that the horizontal orientation resulted in higher mechanical strength, lower surface roughness, and reduced adhesion of Candida albicans. In contrast, printing at 90° yielded the poorest outcomes in the analyzed parameters. Similar results were found in another study6 that tested eight different angulations and found that only the 0° and 90° positions exhibited dimensional accuracy within clinically acceptable limits, while intermediate oblique orientations caused greater distortions.

A narrative review7 highlighted that horizontal orientation resulted in smoother surfaces and faster printing speed, although it requires more supports and allows a smaller number of pieces per cycle. On the other hand, vertical printing enables larger-scale production, but with rougher surfaces and longer fabrication time.

Corroborating these observations, another experiment⁸ was conducted with different resins and orientations, subjecting the samples to mechanical testing after thermocycling. The 0° orientation showed the best performance in flexural strength, while the 90° showed the worst mechanical performance.

Still in 2023, another narrative review9 reinforced that the greater roughness resulting from vertical orientation may compromise the aesthetics and comfort of the aligners, while horizontal orientation, by forming fewer layers, results in devices with better surface finish.

An in vivo study10 compared the surface roughness of DPAs and Invisalign® aligners before and after seven days of use. Initially, the DPAs exhibited a smoother surface, but this advantage was lost with intraoral use, demonstrating that clinical abrasion directly affects the material's texture, regardless of the manufacturing technique.

Orthodontic retainers printed using SLA and DLP technologies were evaluated11 at 0° and 90° orientations. Horizontal printing proved superior in terms of linear accuracy and shape stability, being decisive for the result, which reinforces the importance of print orientation as a critical variable.

A systematic review12 based on 14 studies confirmed that horizontal print orientation was associated with greater dimensional accuracy, lower material consumption, shorter production time, and reduced costs. Although the study did not include directly printed aligners, the authors suggest that the identified benefits are applicable to this type of device, especially in clinical and laboratory workflows.

The surface roughness typically associated with vertical printing may be exacerbated by clinical use, resulting in microcracks and loss of transparency, which compromises both the structural integrity and aesthetics of the aligner, according to another study.13 The findings reinforced that configuration minimizing the number of layers-such as horizontal printing-may be more advantageous for preserving structural integrity, patient comfort, and aligner aesthetics during clinical use.

Another experiment14 confirmed these findings by observing that samples printed at 0° presented greater flexural strength, smoother surfaces, and higher hardness compared to those printed at 45° and 90°, even when using resins intended for provisional restorations.

Other authors15 evaluated the effects of orientation (45°, 60°, and 90°) and layer thickness on aligners printed with TC-85DAC resin (Graphy, Seoul, South Korea). They found that 90° and thinner layers (50 μm) favored aesthetics and reduced surface roughness but did not significantly affect mechanical strength importantly, the horizontal orientation was not included in this study.

In another study,16 the authors also compared the 0° and 90° orientations using test specimens and aligners printed with TC-85, and found no significant differences in mechanical properties, suggesting structural equivalence between the two positions tested. A similar result was observed by other authors17 who evaluated different wall thicknesses and printing angles using TC-85DAC resin and found no statistically significant influence of orientation on flexural strength.

However, when analyzing surface finish, it was demonstrated18 that printing at 0° resulted in lower roughness and higher gloss, outperforming the oblique orientations recommended by manufacturers for both Dental LT Clear (Formlabs, Somerville, MA, USA) and TC-85 DAC.

Finally, another author19 argues, based on extensive literature review and laboratory experience, that the horizontal orientation provides not only better clinical and aesthetic performance but also up to 65% savings in resin, reduced production time, and less need for abrasive finishing, promoting a more sustainable and efficient workflow in the fabrication of direct-printed aligners.

Although often treated as a secondary technical parameter, 3D print orientation proves to be a variable of substantial impact on the performance of printed dental devices. From the analysis of the reviewed studies, a clear contrast emerges between guidelines that predominantly promote printing at oblique angles (generally between 30° and 60°) and laboratory and clinical findings that support the superiority of horizontal (0°) and, in some contexts, vertical orientations.7,20-23

As shown, under certain post-curing conditions, print orientation may indeed not significantly affect the dimensional accuracy of DPAs.4 However, this neutrality does not extend to other properties of DPAs, such as flexural strength, surface finish, and microbial adhesion, where the literature strongly favors the horizontal orientation. Several authors5,6,8 have demonstrated that printing at 0° promotes lower surface roughness, greater mechanical strength, and lower error rates, outperforming both vertical and oblique orientations. These findings contrast directly with the intermediate angulations suggested by manufacturers, and this paradox becomes even more evident when considering that surface roughness not only compromises the aligner's aesthetics but may also influence bacterial adhesion and patient comfort.

Although one study7 acknowledges that vertical orientation allows a greater number of devices per printing cycle, this gain in productivity comes at the cost of inferior surface finish and prolonged printing time -a trade-off not always justifiable in clinical workflows that demand precision and aesthetics. This tension between production efficiency and final product quality is widely discussed by other authors,11,12 who show that the position of the object on the print platform may be more decisive for device fidelity than the printing technology itself (SLA or DLP).11

On the other hand, it is important to note that some findings16,17 mitigate the influence of print orientation on structural resistance, indicating that, for certain resins such as TC-85DAC mechanical performance may remain stable despite differences in positioning. This suggests that orientation should not be considered in isolation but always in conjunction with material formulation and printing parameters (layer thickness, curing time, internal geometry, among others).

One study15 found that in TC-85DAC aligners, 90° orientation and 50 μm layers enhanced aesthetics and surface smoothness without affecting mechanical strength; however, horizontal orientation was not assessed.

Nevertheless, a study18 clearly demonstrates that horizontal (0°) orientation still provides the best initial aesthetic finish with greater gloss and lower roughness -outperforming even the manufacturers’ official recommendations. These findings, combined with a practical and sustainable analysis,19 consolidate horizontal printing as not only a viable but a preferable alternative from a technical, economic, and clinical perspective (Figure 2 A & 2B).

Figure 2 Clinical images of direct- printed aligners (DPAs) fabricated in the horizontal orientation (0°).

A: Close-up view highlights the high gloss and smooth surface of the freshly printed device, without any mechanical polishing. B: DPA after 15 days of intraoral use, maintaining structural integrity and preserved aesthetic finish.

From a clinical perspective, print orientation has a direct influence on the aesthetics, comfort, and durability of aligners. Smoother surfaces-such as those achieved with the horizontal position-tend to reduce biofilm retention and the potential for soft tissue irritation, as well as promote greater transparency and preservation of appearance over time. According to available studies, flexural properties do not show clinically relevant differences among different print orientations. However, considering the additional advantages of the horizontal position-such as lower resin consumption and shorter manufacturing time-this configuration supports more sustainable and cost-efficient laboratory practices. These factors reinforce the importance of treating the choice of print orientation as a strategic decision in clinical planning.

In summary, the discussion surrounding print orientation in directly printed aligners is far from merely operational. It is a strategic choice that requires balancing productivity, aesthetics, comfort, mechanical performance, and sustainability.

The alignment between scientific evidence and market practice remains limited, and it is up to the academic community -based on studies such as those presented here -to contribute to the redefinition of protocols that prioritize the quality of patient care, even if this means moving away from standardized commercial models.

There is a divergence between commercial guidelines and scientific evidence regarding the optimal orientation for printing DPAs, based on the most recent literature. The findings reveal that adjustments in print orientation can lead to significant improvements in DPA properties without compromising manufacturer-established protocols. Studies show that horizontal positioning (0°) reduces roughness, preserves flexural strength, and enhances aesthetics, in addition to reducing resin consumption and accelerating production. These advantages suggest a more rational use of resources and more sustainable laboratory practices. However, the adoption of this strategy must be supported by further clinical and laboratory investigations. Therefore, it is essential to broaden the scientific discussion and validate printing protocols based on evidence-based data.

None.

The authors declare that there are no conflicts of interest.

©2025 Bacci, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.