Journal of

eISSN: 2373-4345

Research Article Volume 12 Issue 4

1Department of Prosthodontics and Dental Materials, São Paulo State University (Unesp) – Institute of Science and Technology, São José dos Campos, Brazil

2Department of Dentistry, School of Dentistry, University of Taubaté (UNITAU), Brazil

Correspondence: Dr. Tribst JPM, School of Dentistry, University of Taubaté (UNITAU), Operários street 09, Taubaté, SP, Brazil

Received: August 31, 2021 | Published: November 19, 2021

Citation: Nakano LJN, Tribst JPM, Dal Piva AMO, et al. Maximum fracture load and stress concentration in resin-bonded fixed partial dentures of indirect composite resin reinforced by silica-nylon mesh. J Dent Health Oral Disord Ther. 2021;12(4):96-101. DOI: 10.15406/jdhodt.2021.12.00558

Objectives: This study aimed to evaluate the maximum fracture load using a silica-nylon reinforcement system on resin-bonded fixed partial dentures (RBFPD) made of indirect composite resin.

Methods: An in vitro test simulated an anterior (A) and posterior (P) three-element RBFPD. Thus, 80 specimens were made in 8 experimental groups (n = 10). The groups were divided according to the silica-nylon reinforcement presence (R) and aging (C). The aging process was performed through mechanical cycling for 106 cycles at 4 Hz. The samples were tested by maximum fracture load in a universal testing machine with a 1000 Kgf load cell and analyzed by Stereomicroscope and Scanning Electron Microscopy (SEM). Statistical analysis consisted of analysis of variance (two-way ANOVA) and Tukey test 5%. An in silico study was performed by Finite Element Analysis (FEA), in which the abutment teeth and the prostheses were scanned and transferred to CAD Rhinoceros (version 4.0SR8; McNeel North America, Seattle, WA) for 3D modeling. The analysis test was performed in computer aided engineering software (ANSYS 19.3, Canonsburg, PA, USA).

Results: The maximum fracture load results (N) were A=163.55; AC=184.48; AR=198.81; ARC=192.24; P=539.99; PC=359.61; PR=541.74 and PRC=608.74. The Maximum Principal Stress results obtained in the FEA were (MPa): A=53.24/122.40; AR=55.07/117.70; P=33.28/36.18 and PR=28.06/42.87.

Significance. It was concluded that the presence of the silica-nylon mesh increased the maximum fracture load of the RBFPD without increasing the stress concentration, regardless of the prosthesis design.

Keywords: Resin-bonded denture, nylon, composite resins, finite element analysis, dental materials

Resin-bonded fixed partial denture (RBFPD) is a treatment option to replace a lost dental element. A variety of designs can be used such as metalloceramics, all-ceramics and composite resins.1,2 Compared to other materials, composite resins have advantages of lower cost, elastic modulus similar to teeth, less abrasion on the antagonist tooth, possibility of repair and great aesthetics.3,4 Despite the acceptable characteristics of composite resins, several studies have investigated the use of reinforcements to improve the mechanical properties of this material.5-7

RBFPDs are commonly indicated for the anterior region,8,9 and in some cases for the posterior region. They are a less invasive treatment than dental implants and conventional fixed partial dentures. They are reversible and can be indicated for temporary or permanent rehabilitation. Even so, failures such as debonding or fractures are reported in the literature and cause insecurity for dentists to recommend this treatment.10 The incidence of masticatory loads applied to the structure of RBFPDs can generate stress and strains,9 and can cause structural failure when these become excessive and exceed the elastic limit of the materials.11 Therefore, the restorative materials used for its manufacture must have mechanical properties which are capable to resist the stresses caused by masticatory loads.12 In addition, different types of fibers have been used in order to reinforce the restorative materials, such as fiberglass, aramid, polyethylene and nylon.11,13-16

A silica-nylon reinforcement system was developed with acrylic resin and composite resin prostheses.17 It is composed of 6.0 nylon and 0.5% silanized silica volume to increase the chemical bond of the reinforcement to polymeric materials.18 This reinforcement showed promising results regarding fracture resistance in temporary fixed partial dentures of bis-acrylic resins and complete-arch implant-supported prostheses of acrylic resin.19,20 Its use as a RBFPDs reinforcement in indirect composite resin still need to be properly evaluated for anterior region.21

It is important to study how the presence of the silica-nylon reinforcement can modify the stress generated in the prosthesis and how the fracture mode and load to failure can improve the treatment prognosis for cases rehabilitated with RBFPDs. To do so, in silico and in vitro methods can be applied to simulate this treatment. In view of the promising results of silica-nylon reinforcement, this study aimed to evaluate the influence of this reinforcement on resin-bonded fixed partial dentures made of indirect composite resin in relation to the maximum fracture load and stress distribution, and submitted to the aging process. The hypothesis of the study was that the presence of reinforcement would improve the mechanical properties of RBFPDs in the short and long term.

Specimens preparation

Eighty (80) specimens were made and divided into 8 groups (n = 10) according to: region (anterior or posterior), silica-nylon reinforcement (presence or absence) and aging (yes or no). A mannequin model (P-Occlusal Mod. 08 Arc. Superior, São Paulo, Brazil) was used to perform tooth preparations. Teeth 11, 22, 25 and 27 were prepared according to the preparation standard for resin-bonded fixed partial dentures.22 The preparation characteristics of the anterior teeth were: lingual reduction of 0.5 mm depth, ending in a short chamfer, and occlusogingival dimension of 1 mm above the cementoenamel junction up to 2 mm below the incisal edge; while the preparation characteristics of the posterior teeth were: reduction of 0.5 to 1 mm depth of the lingual and proximal surfaces, ending in a short chamfer, occlusogingival dimension of 2.5 to 3 mm, 1 mm depth occlusal groove, 2 mm of buccolingual and 1.5 mm mesiodistal distance.

The prepared teeth were molded with silicone-based polymeric material (DRAF Comercial, São Paulo, Brazil) and the molds were filled with epoxy resin (Epoxis LE 100 DRAF Comercial, São Paulo, Brazil) to produce 40 upper central incisors, 40 upper lateral incisors, 40 upper second premolars and 40 upper second molars, totaling 160 teeth.

The abutment teeth were demarcated 2 mm below the cementoenamel junction and the root portion was covered with red wax. Each set of epoxy resin anterior teeth were included on a cylindrical silicone mold (25 x 15 mm) and the posterior teeth on a rectangular mold (35 x 20 x 15 mm), containing polyurethane resin (Resin F160 Axson, Cergy, France), with the aid of a dental delineator (Bio art, São Paulo, Brazil). After polymerization of the polyurethane resin, the abutment teeth were removed from the artificial alveolus and cleaned with hot water to remove the wax. The addition silicone (Variotime Kulzer GmbH, Hanau, Germany) was inserted into the alveolus and the abutments introduced under digital pressure until the 2.0 mm marking of the cementoenamel junction coincided with the surface of the polyurethane resin base in order to simulate the periodontal ligament.23

The first step to use the silica-nylon mesh to produce reinforcement prostheses was the dimensioning, the size standardization and the sandblasting with 50 grit aluminum oxide (Bio-art, São Carlos, Brazil), pressure of 2.8 bar, distance of 20 mm from the surface (Sandblaster III Trijato Goldline, Araraquara, Brazil), and subsequent cleaning with distilled water in an ultrasonic cleaner. Futurabond M universal adhesive (VOCO, Cuxhaven, Germany) was applied to the mesh, photoactivation was performed and it was positioned in the preparations with portions of composite resin using a silicone guide.

The first anterior and posterior prosthesis was made of acrylic resin (VIPI Cor, São Paulo, Brazil) using the over impression fabricated technique. A guide was subsequently produced with a transparent 2 mm silicone plate (Whiteness FGM, Santa Catarina, Brazil) to standardize the prostheses. Indirect light-cured nanohybrid composite resin (NanolabZ WILCOS, Petrópolis, Brazil) color A2 was applied in 2 mm increments and photoactivated with a Bluephase LED device (Ivoclar Vivadent, Schaan, Liechtenstein). The finishing was done with diamond tips, the initial polishing with pumice slurry and water with a goat hair brush, and the final polishing with wool disks and polishing paste (Poli Universal Asfer, São Caetano do Sul, Brazil).

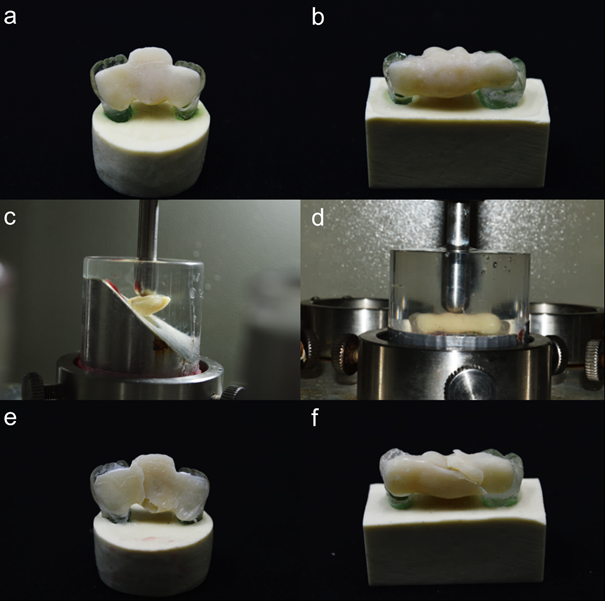

A universal adhesive was applied to the abutment teeth to cement the prostheses, and dual-cured resin cement BIFIX QM (VOCO, Cuxhaven, Germany) was then applied on the prostheses and seated on the teeth. The excess cement was removed and photoactivated for 20 seconds each side. The specimens were stored in distilled water (37ºC) for a period of 24 hours (Figure 1).

Figure 1 In vitro samples of anterior (a) and posterior (b) design. 45° degree anterior sample (c) and posterior sample (d) parallel to horizontal plane during loading incidence. Representative failed samples in anterior (e) and posterior (f) design.

Aging protocol

Half of the specimens were subjected to mechanical cycling during 1,000,000 cycles at 4 Hz frequency in a humid environment at 37 ± 1ºC in a masticatory cycle simulator (ERIOS mechanical cycler, Model: ER-11000 Plus, São Paulo, Brazil). The anterior specimens were positioned at 45° with the applicator tip in the central palatal region of the pontic with a load of 100 N. The posterior specimens were positioned parallel to the horizontal plane with the 200 N load applied to the occlusal surface of the pontic (Figure 1). After cycling, the prostheses were subjected to the resistance test up to the maximum fracture load.

Compressive testAll specimens were submitted to the maximum fracture load test carried out with a 1000 Kgf load cell and speed of 1.0 mm/min with the same applicator tip used in the mechanical cycling and the same sample positioning (EMIC DL 1000, São Paulo, Brazil). Thus, the specimens were subjected to compressive load until fracture and their maximum load values were recorded in Newton (N) (Figure 1). A representative sample from each group was subjected to fractographic analysis in stereomicroscopy (Discovery V20 Carl Zeiss, Jena, Thuringia, Germany) and Scanning Electron Microscopy (Inspect S 50, FEI Company, Brno, Czech Republic).

Statistical analysis

The statistical analysis was performed using the MINITAB program (Minitab, version 17.1.0, 2013). The results of maximum fracture load were subjected to analysis of variance (two-way ANOVA) and the Tukey test at 5% significance.

Finite Element Analysis pre-processing

The prepared abutment teeth and a specimen of anterior and posterior prosthesis were scanned by a scanner (Ceramill Map 400, Amann Girrbach, Austria) and stereolithographic files (.stl) were obtained. Next, these files were transferred to the CAD Rhinoceros software (version 4.0SR8; McNeel North America, Seattle, WA) to elaborate the 3D volumetric model, in which the models were produced within the BioCAD protocol.24 Thus, three-element prostheses were simulated, being similar to the situation performed in the in vitro analysis. Four different situations were modeled according to the region (anterior and posterior) and the presence of the reinforcement. Human anatomy was used to construct the periodontal ligament dimension patterns, and the drawing was performed with a thickness of 0.3 mm.25 Cement layers were made according to clinical acceptability with a thickness of 50 µm.26

Processing

After modeling, the geometry was exported in STP format to the analysis software (Ansys 19.3 - ANSYS, Inc. Southpointe, Canonsburg, USA) where the models were converted into finite element mesh. The elastic modulus (E) and the Poisson ratio (ν) of each material were assigned to perform the structural static analysis (Table 1). All the materials present in the composition of the system were considered homogeneous, isotropic and linearly elastic.

Materials |

E (GPa)* |

V* |

Composite resin |

12.825 |

0.26 |

Silica-nylon reinforcement |

1.9 |

0.17 |

Resin cement |

8.0 |

0.24 |

Epoxy resin |

2.31 |

0.49 |

Polyurethane |

3.6 |

0.3 |

Addition silicone |

0.068 |

0.45 |

Table 1 Elastic modulus (E) and Poisson ratio (ν) of the materials used in the finite element analysis

*Data obtained from the pulsed excitation technique (ATCP Sonelastic, UNESP ICT, São José dos Campos, SP, Brazil).

All connections between the elements (prosthesis, nylon mesh, cement, tooth, periodontal ligament and base) were considered bonded contacts. The bottom surface of the base was fixed in all directions with zero displacement, thus defining the boundary conditions.

In relation to loading, a static load of 100 N was applied to the central region of the palatal face of the pontic of the anterior prostheses and a 200 N load in the occlusal region of the pontic of the posterior prostheses in order to simulate the clinical situations and similarly for the load applied in the in vitro analysis (Figure 2). A mesh convergence test (10%) was performed to ensure that the mesh would not interfere in the results. Von Mises stress and total deformation analyzes were performed for the coherence test in order to verify the reliability of the contacts, fixings and loads. Maximum principal stress criteria were used to evaluate the results.

The groups in the anterior and posterior regions were analyzed separately to statistically evaluate the data. For the anterior groups, two-way ANOVA showed statistical difference for the reinforcement factor and the Tukey test (at 5%) found that reinforcement groups showed superior results (Table 1).

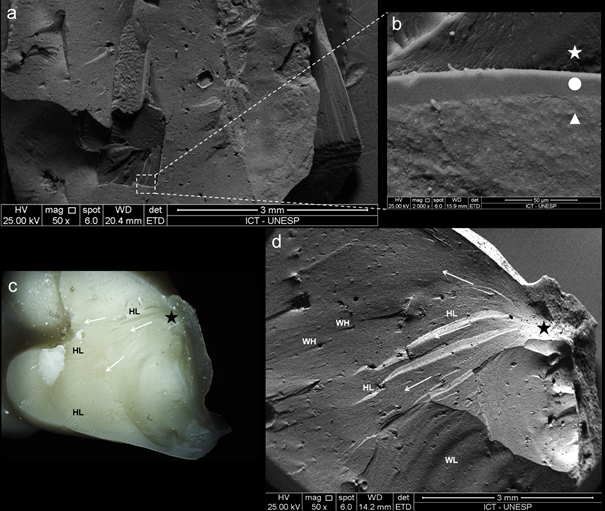

The results of the two-way ANOVA from the posterior groups showed that all factors (reinforcement, aging, and interaction of reinforcement with aging) showed statistical differences (p-values). The Tukey test at 5% showed that the reinforcement groups showed superior results, the aging groups showed inferior results, while the aging group without reinforcement had the lowest results. Fractographic analysis showed that all prostheses failed with the same pattern in the region of the connector between the pontic and the central incisors, and between the pontic and the second molar. The reinforced prostheses did not present separation of the components after the fracture. The SEM images of the posterior sample show the fracture characteristics, direction of crack propagation and fracture origin, which occurred in the lower and buccal region of the pontic close to the molar connector. In addition, it was possible to view the materials in the reinforcement-prosthesis interface in the reinforced samples (Figure 3).

Figure 3 Images of fracture surfaces in stereomicroscope and SEM of anterior and posterior prostheses. Anterior reinforcement sample under 50x magnification (a) and interface between the silica-nylon mesh and composite resin under 2000x magnification (b). White star - nylon; Circle - adhesive; Triangle - composite resin. Posterior sample in stereomicroscope under 7.5x magnification (c) and the same sample in SEM under 50x magnification (d). Black star - fracture origin; Arrow - direction of crack propagation; HL - hackle lines; WH - Wake hackles; WL - Wallner lines.

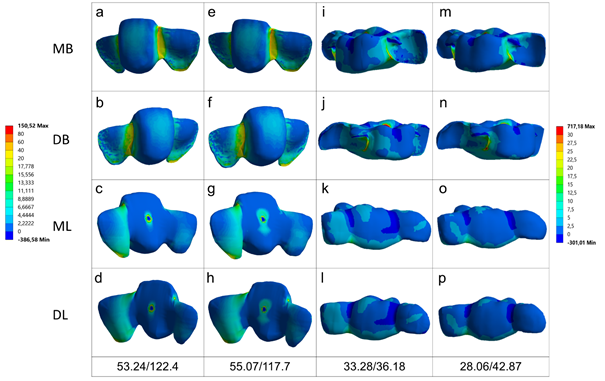

The results obtained from the maximum principal stress suggest that the stress concentration is similar between the evaluated groups. Based on the stress peaks, the probability of fractures occurring in the connection regions between the pontic and the central incisor, and between the pontic and the second molar, was higher than in the lateral incisor and second premolar, regardless of the groups evaluated. Thus, the presence of silica-nylon reinforcement does not increase the stress concentration in the RBFPDs (Figure 4).

Figure 4 Maximum Principal Stress generated in the resin-bonded fixed dental prostheses according to the region and presence of reinforcement. Anterior control model (a-d), anterior reinforced model (e-h), posterior control model (i-l) and posterior reinforced model (m-p). Four viewports: mesiobuccal (MB), distobuccal (DB), mesiolingual (ML) and distolingual (DL). Stress peak calculated for each retainer is presented in MPa (Distal retainer/Mesial retainer).

This study evaluated the influence of silica-nylon reinforcement in resin-bonded fixed partial dentures made of indirect composite resin in relation to the maximum fracture load and stress distribution. The study hypothesis was accepted, since the presence of the reinforcement improved the mechanical properties of the prostheses and the resistance to the maximum fracture load results showed a statistical difference.

Prosthetic restorative treatment aims to restore shape and function through restorations which support masticatory loads and failures caused by occlusal loads. For this reason, several authors have studied mechanisms to increase the fracture resistance of the materials used in prostheses such as the use of reinforcement fibers, for example, glass, aramid and nylon.13-15 This search to improve the mechanical properties was the main reason to use silica-nylon mesh as reinforcement in resin-bonded fixed partial dentures made of indirect composite resin.

The in vitro study sought to simulate the clinical situation. For example, the use of impression material in thickness similar to the periodontal ligament.23,27,28 In addition, the sample bases were made of polyurethane resin, because they are isotropic and have a similar elasticity module to the medullary bone (Polyurethane - 3.6 GPa and medullary bone - 4.0 to 4.5 GPa).29,30

The aging process through mechanical cycling aims to simulate the fatigue of the material in a similar way to what would happen in function. Basically, it is necessary to adjust the force applied to the samples, the number of cycles, and the frequency (Hz), which is the number of cycles per second. There are several studies in the literature with great variation in the masticatory load values due to the difficulty of measuring these values and the difference between the methods.31-35 Force during chewing in healthy individuals varies between 70 and 200 N.36 For this reason, the load used to perform mechanical cycling was 100 N for the anterior region and 200 N for the posterior region. The load in the anterior region was applied in the central palatal region of the pontic,9 while the load in the posterior region was applied in the occlusal region of the upper first molar simulating normal occlusion.37

There were 1,000,000 cycles performed on the samples, which corresponds to approximately 4 years in the oral environment,38-40 in addition to being immersed in water at a temperature of 37ºC, which corresponds to the oral temperature.41 Furthermore, 4 Hz was used for the frequency, which is similar to the physiological frequency performed during chewing of around 3 to 4 Hz.42

This mechanical cycling can influence the development of cracks in the load concentration areas and inside the samples, which can fuse and weaken the prosthesis body when subjected to many repetitions, thus facilitating its failure in greater efforts.43,44 This was proven in this study, in which it is possible to verify that the mechanical cycling aging negatively affected the maximum fracture load in posterior groups. It can be inferred that the presence of the reinforcement improved the material resistance under monotonic test in axial load through the results and statistical analyzes of maximum fracture load, both in the anterior and posterior prostheses (Table 2). These results corroborate previous studies,19,20 who used the same reinforcement material in other therapeutic modalities. This result can be explained by the presence of the mesh inside the prosthesis to keep the resin structure together around it, making it difficult to propagate cracks and suggesting toughening of the restorative system.

The reinforced posterior prostheses in this study showed significant results compared to prostheses without reinforcement. This can be explained by the incidence direction of the load applied on the silica-nylon reinforcement. In this case, the mesh was applied in the vertical direction and the load was exerted in the same direction, thus there was a greater flexural strength of this material due to the mesh architecture itself. In the case of the anterior prosthesis, the mesh was also applied in the vertical direction; however, the load was applied at 45º, which promoted greater flexion and consequently less capacity to strengthen the prosthesis. Previous studies corroborate this information that the architecture and direction of the incidence load influence the fracture resistance of the material.45,46 However, in bisacrylic resin temporary fixed prostheses,19 the fiber in the horizontal direction showed better results, which contradicts the results obtained in this study. This disparity may have been caused by the difference in the material used to manufacture the prostheses and their anatomies.

Regarding the maximum fracture load values, there is no consensus in the literature on the maximum force applied in the oral environment. Several studies have different methodologies and values, but the average found was 100 to 200 N in the incisor region, and 300 to 600 N in the molar region.31,32,47 The values obtained in this study are in accordance with the loads found in the literature and would be able to resist the forces occurring in the oral environment, even more so considering that occlusal loads are not normally applied to only one tooth, but are distributed across the dental arch.

The most common fracture sites in the anterior region were the connector between the pontic and the central incisor, and the connector between the pontic and the molar in the posterior region. This was proven through the finite elements analysis, in which the greatest stress concentration occurred in the connector of the central incisor and in the molar connector (Figure 4). This can be explained by the shape and presence of more acute angles in these regions of the prostheses, thus showing that not only the thickness influences the resistance of the material, but also the anatomy of the prosthesis can lead to stress concentration and consequently fracture.1

In this study it was found that the presence of nylon reinforcement inside the RBFPDs promotes a more favorable fracture pattern, with no separation of the fractured parts. Thus, the patient in a clinical situation would be able to maintain it without aesthetic damage, even with the prosthesis failure, and it could still be used for a short period as a “temporary element” until its replacement. With the failure only occurring in resin and the mesh remaining intact, it can be inferred that there was no catastrophic failure in the reinforced prostheses, which corroborates previous studies.19

In the fractographic analysis obtained through stereomicroscope and scanning electron microscopy, it is possible to verify the near contact between the silica-nylon fiber, the resin matrix and the adhesion of nylon-adhesive-composite resin interface. In addition, it is possible to see the direction of crack propagation from the tension side (lower and vestibular region) to the compression side (upper and palatal region) and the fracture origin (Figure 3) in both the stereomicroscope and SEM images, which was proven through finite element analysis.48,49

In addition, the results obtained from the in silico analysis showed similarity to the results found in the in vitro test, mainly in relation to the fracture origin. Thus, it is possible to infer that there was method validation by finite element analysis for the methodology used in this study, and that the use of silica-nylon reinforcement positively influences the resistance to the maximum fracture load of the RBFPDs made of indirect composite resin.21 Thus, it is necessary to carry out new clinical studies to better understand the behavior of this type of prosthesis to elucidate and consolidate the results obtained so far, as well as the use of silica–nylon mesh in different polymeric biomaterials.50

Through the results obtained in this study, it was concluded that the presence of the silica-nylon mesh increased the maximum fracture load of the resin-bonded fixed dental prostheses without increasing the stress concentration, regardless of the prosthesis design.

None.

The authors acknowledge the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) through the process no. 88882.434238/2019-01.

No potential conflict of interest relevant to this article was reported.

©2021 Nakano, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.