Journal of

eISSN: 2378-3184

Research Article Volume 14 Issue 2

Universidad Autónoma de Nuevo León, Facultad de Ciencias Biológicas, Grupo Ecofisiología, Mexico

Correspondence: Roberto Mendoza Alfaro, Universidad Autónoma de Nuevo León, Facultad de Ciencias Biológicas, Grupo Ecofisiología, San Nicolás de los Garza, Nuevo León, México

Received: May 07, 2025 | Published: May 13, 2025

Citation: Gámez AA, González CJA, Luna-Peña S, et al. Cost-effective method to automatically record and regulate temperature with an open-source microcontroller in a tilapia recirculating aquaculture system. J Aquac Mar Biol. 2025;14(2):61‒68. DOI: 10.15406/jamb.2025.14.00416

The culture of tilapia has spread around the world. However, developing this technology in semidesert climates with limited water supplies, like Nuevo León, Mexico, necessitates using methods that address these issues while having a minimal economic impact. Water scarcity has been solved through recirculating aquaculture systems, RAS. While temperature control remains a challenge that must be adapted to the climate conditions of each region. For the reasons above, a closed-loop water heating system for tilapia production in RAS within a greenhouse in Nuevo León was assessed in the current work using basic and affordable components. Energy produced by a home water heater can be transferred quickly and effectively using a hydraulic system with a copper heat exchanger. The Arduino® IDE, a free integrated development environment, controls the heater's flame activation. This comprises temperature sensors in the fish tank and the hydraulic heating system's water reservoir. As a result, the winter temperature of the fish culture water tank was successfully regulated to be kept between 27 and 28 degrees Celsius, which is considered to be ideal for tilapia. In terms of initial investment and operating costs, the suggested system is superior to alternative solutions.

Keywords: RAS, greenhouse, temperature control, closed loop system, cost-effective, open source, arduino® platform, dependable supplier

The most prevalent aquaculture activity worldwide is tilapia farming, which includes Nile tilapia and numerous other cichlid species.1 It is the second most common aquaculture species globally, behind carps. México along with other countries has a high tilapia demand,2,3 which according to government statistics is mostly met by imports from China,1,4,5 Despite being one of the most significant locations for tilapia consumption, the northeastern Mexican state of Nuevo León has the second-lowest national production. This is because of the semidesert region's erratic climate and water constraint.

The climate in the southernmost parts of the United States and northern Mexico allows tilapia to live in open-water ponds all year round. In the other parts of the United States, however, tilapia must be overwintered inside buildings that are adequately insulated and heated to maintain the water temperature.6 The reality of the tilapia production model in northern Mexico is that the technology created for fish production heavily utilize limited resources, such water. Therefore, water exchange is frequently used as a way to lower waste concentrations, lower ammonia levels, or dilute plankton to prevent a sharp decline in dissolved oxygen levels.7,8 Recirculating systems are utilized as a result of this method, which reduces water consumption. Nonetheless, this implies that careful observation of the water quality parameters required for tilapia to grow healthily is necessary.6,9 However, until recently, recirculating systems were mostly used in research facilities and were rarely used by profitable commercial enterprises. This was mainly because of the high overhead administration costs.10,11 Within this context, tank culture of tilapia has been considered a good alternative to open systems where there is a shortage of land or water, and the supply of production factors and the demand for goods and services are favorable.6,9

The first component impacted by the region's severe winters is water temperature, which is one of the most important factors for tilapia. Stickney10 distinguishes between conservative physical features of aquatic systems, such as dissolved oxygen, pH, ammonia-ammonium ion complex (NH3/NH4+1), nitrite (NO2-1), and nitrate (NO3-2), which are clearly impacted by fish metabolism; and non-conservative: volume, density, and temperature that are not strongly altered by fish activity, the latter being the most important non-conservative physical attribute for aquatic species.

Tropical tilapias are resilient creatures that can withstand a variety of water conditions, including temperature. Although the ideal temperature range for the growth of must strains of tilapia under aquaculture conditions is 27°C to 29°C, the temperature tolerance range varies by species.9 There are benefits to maintaining strict control over the water temperature because it enables the farmer to make administrative decisions based on benefit-cost analysis. According to DeLong,9 optimal growth rates can be achieved between 25 and 32 degrees Celsius. It is important to note that keeping the water temperature in the upper temperature range makes it more difficult to maintain dissolved oxygen levels within acceptable bounds. This has significant economic implications when one considers the cost of heating water with the growth rate increase brought about by temperature control, as well as the additional expense of dissolving more oxygen when the solubility of gases in water is inversely correlated with temperature and the rate at which fish breathe.

On the other hand, according to Webster and Lim,12 Ichthiophthirius multifiliis, also referred to as white spot, is a parasite in tilapia cultures that is found all over the world and represents one of the most significant infections in systems that use recirculating water. Temperature is one of the most crucial elements in the development and length of its life cycle when the conditions are right for it to proliferate quickly.12 High mortalities in tilapia, due to the parasite, have been reported at a temperature range of 20oC to 25oC, and it has been proposed that keeping the temperature within the range that is ideal for tilapia development may help to reduce the outbreak's intensity.12,13 However, this represents a serious challenge because from the standpoint of the producer, it is convenient to have tilapia grow in the winter months in northeast Mexico by keeping the water temperature close to the ideal range to reach market size just after that season, when demand is high and so are market prices.

The aquaculture industry's explosive growth in recent years has prompted the creation of new methods and techniques, one of which is the necessity of automating several production phases.14 Thus, tilapia can be produced in areas with year-round water scarcity and climate variability that are near major consumption centers like Monterrey, Nuevo Leon, Mexico, thanks to the use of microcontrollers in greenhouse tilapia culture and water recirculation, which enable reliable monitoring and control of parameters like temperature. In a recirculating aquaculture system (RAS), maintaining water temperature within a certain range involves two approaches: the electronics approach and heat transfer, where the majority of the energy is transferred as heat. Precision and efficiency are simultaneously made possible by this combination of thermodynamic systems and electronics. Because of the high enthalpy of evaporation of water (2,250KJ/Kg), (change of state) during the winter months accounts for a significant portion of the heat lost by the system to its surroundings if left unchecked,15,16 Covering it allows it to condense and recover the heat as enthalpy of condensation, which is readily overcome. A closed or open loop system can be used to regulate the temperature in a RAS. The heating element is turned on and off for a predetermined period of time, achieving an open loop system regardless of the initial or intermediate temperatures. Although this approach is easier, the target temperature is not always obtained. The closed loop approach, on the other hand, uses one or more feedback mechanisms and allows the use of relatively cheap components to get the precise temperature, but it has a bigger issue with system stabilization.17 Given the foregoing, the purpose of this study was to evaluate the effectiveness of a low-cost closed-loop system that would allow for the monitoring and control of water temperature.

The law of conservation of energy was considered with regard to the hydraulic circuit, which was constructed based on the amount of heat required to raise the water temperature in the fish tank. First, the system's boundaries were established. In this instance, the boundaries are the walls of the tank and the water's surface, and the system's limits match the heated water inside the fish tank, which takes on the shape of a container. The copper tube, also known as the heat exchanger, is the component of the system that permits energy to go from an area of higher temperature to one of lower temperature when it comes into physical contact with the water in the tank.

To establish the energy balance, the following considerations were made: heat flows radially in one direction, no work is done by or to the system in virtue of the water temperature difference, the force of gravity has no effect due to the differences in elevation within the system, no heat is generated or accumulated in the heat exchanger, and the thermal conductivity remains constant within the variations of temperature in the system.

The energy balance is reduced to the following statement by accounting for the previously mentioned factors: dE/dt = dQ, which states that the change in the system's internal energy per unit of time equals the change in the amount of heat.

The function Q = mCpΔT was used to calculate the amount of heat, where m is the water's mass in kilograms, Cp is its heat capacity in kJ/(kg°C)-1, and ΔT is the temperature differential in degrees Celsius between the initial temperature Ti and the final temperature Tf. The fish tank's measurements (diameter = 1.7m and height = 1.0m) were used to determine the water mass, taking into account an operating level of 0.7m. The mass of the water in the fish tank was 1,500kg, which was calculated by multiplying the water volume (1.5m3) in the cylinder by the water density (1 ton/m3). As seen in Tables 1&2, the energy needed to be transferred to reach the ideal temperature was computed using these data and three scenarios.

|

Component |

State |

|||

|

I |

II |

III |

IV |

|

|

General Switch |

off |

off |

on |

on |

|

Electrovalve |

off |

on |

off |

on |

|

Flame |

off |

off |

off |

on |

Table 1 Logic truth table used to control water temperature in the hydraulic heating system: water reservoir and fish tank

|

|

Scenario |

||

|

Temperature/Energy/Power |

1 |

2 |

3 |

|

Tinitial temperature °C (Ti) |

17 |

24 |

28 |

|

Final temperature °C (Tf) |

28 |

28 |

28 |

|

Requiered energy (KW-H) |

19 |

7 |

0 |

|

Suggested power (KW) |

13 |

13 |

13 |

Table 2 Suggested Energy (KW-H) and power (KW) for the heat source to elevate water temperature for 1,500 kg of water in the following range: (17 – 28 °C), (24 – 28 °C) y (28 – 28 °C)

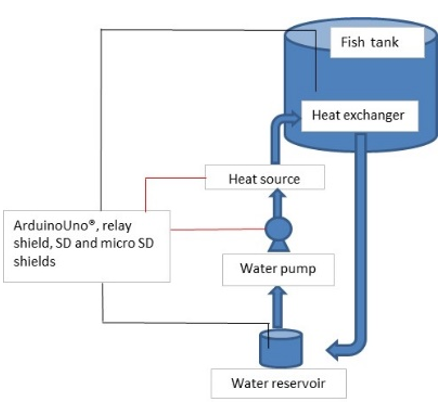

Figure 1 shows the hydraulic circuit that was developed to regulate the temperature of the 1,500-liter tilapia fish tank. One of the circuit's parts is a reservoir with a capacity of 19 liters. A 0.5 horsepower (0.373kW) centrifugal type water pump (Múnich®, model BA-1208, 120 volts, and 6.0 amperes alternating current) was utilized to push the water through the hydraulic circuit. A 13.3kW nominal capacity domestic step boiler (CINSA model CIN-11) served as the heat source. When water passes through the heater, the venturi effect activates an integrated electro-valve. A copper heat exchanger, measuring 4meters in length and 25.4mm in diameter, painted with plasticized paint, was used. Depending on the desired temperature in the fish tank and the water temperature in the heat exchanger's hydraulic circuit, the water pump and heater were activated automatically and separately.

Figure 1 Diagram of the hydraulic circuit and its relation with the control circuit. Temperature sensor lines in black and Power control lines in red.

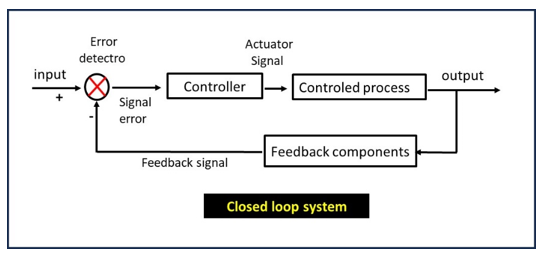

As illustrated in Figure 2, the temperature control method17,18 involved limiting the heat source by using the ArduinoUNO® board to switch it on and off alternately in a closed loop.

Figure 2 Closed loop diagram, the controller corresponds to the ArduinoUNO®. The controlled process is the water temperature in the tilapia tank and del 19 liters heat exchanger water reservoir, the feedback elements are the two sensors DS18B20 and the error detector is the comparator with in the ArduinoUNO®, the signal is sent to the actuators, in this case the water pump and the residential water heater.

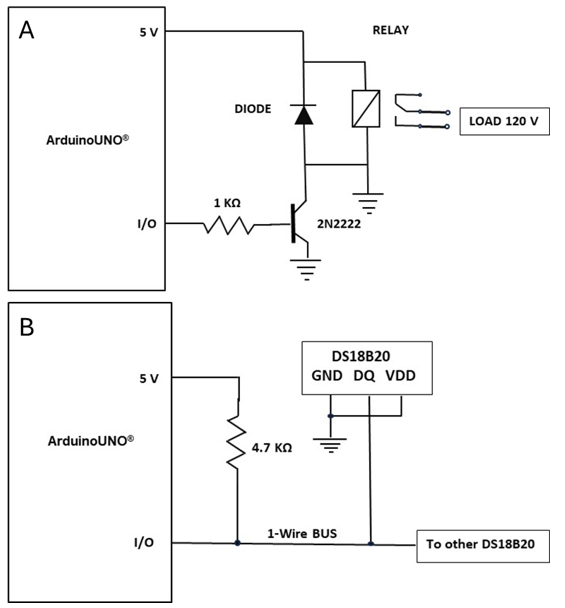

The ArduinoUNO® board is made up of an 8-bit ATmega328P microprocessor that runs at 5 volts. It also features 14 digital input/output pins, six of which are capable of PWM (pulse width modulation), six analog input pins (recommended current 20mA, maximum 40mA), a 3.3-volt feed connector (current of 50mA), and an internal clock (a ceramic oscillator running at 16MHz). The functions MOSI (master out slave in), MISO (master in slave out), serial clock (SCK), RESET (used to restart the main loop), VCC (direct current input), and GND (ground) are also included in the in-circuit programming header (ICSP) of this board. Two remote temperature devices (RTDs) of the Maxim Integrated® DS18b20 type were used to monitor the water temperature in the fish tank and the heat exchanger (Figure 3A). This digital thermometer can generate values between 9 and 12 bits, has a non-volatile programmable function with superior and inferior limits, and connects to the microcontroller via the 1-Wire® connection. Because each DS18b20 sensor has a unique 64-bit code that enables it to connect to the same 1-Wire® bus, controlling several sensors spread across a large area with a microprocessor is easy.

Figure 3 (A) Diagram of the relay interphase control power. (B) Diagram showing the connection of the digital thermometer DS18B20 in parasite mode.

As shown in Figure 3(A), we used a mechanical relay with a 5 -volt direct current (DC) trigger coil that can handle 10 amperes at 120volts of alternating current (AC), a general-purpose bipolar transistor NPN 2222, a diode 1N4007, and a 1-kilo ohm resistance (1K) to control the water pump's alternating on and off state using the Arduino board. As a result, the heater's electro-valve could only activate the ignition spark when the temperature was within the predetermined range. Similar to that, the Arduino board was linked to the general switch using the architecture shown in Figure 3(B) to control the water heater independently. Using this technique, water flow was permitted through the heat exchanger hydraulic circuit with the boiler flame off when the water temperature reached 50°C. This procedure is similar to how an AND logic gate behaves (Table 1).

To load programs and interface with the computer via a serial monitor, the ArduinoUNO® uses an integrated development environment (IDE) platform that is connected to the Arduino® hardware.19,20 With these components, the closed loop system's operation was programmed to adhere to the following guidelines.

State I) The flame is extinguished, the pump and general switch are turned off, the fish tank's water temperature is within the target range of 27 to 28 +/-0.5 °C, and the heat exchanger circuit's temperature may or may not be between 40 and 50 +/- 0.5 °C.

State II) The general switch is off, the flame is off, the temperature in the fish tank is below the target range of 27 to 28 +/- 0.5°C, and the temperature in the heat exchanger is between 40 and 50 +/- 0.5°C.

State III) The flame is off; this is a very short-lived transition condition that occurs when the water pump that starts the flame has not yet begun and the fish tank's temperature has fallen below the desired range.

State IV) Since the water temperature in the fish tank and the heat exchanger circuit is below the designated target, the flame is on, and as a result, the electro-valve and general switch are in the on condition.

This system was assessed at the Ecophysiology group's wet laboratory at the Facultad de Ciencias Biológicas, Universidad Autónoma de Nuevo León. Intermittent tests were conducted to control and record the temperature during the winter of 2014–2015 to achieve this goal.

Using a Seeed studio® SD card shield v3.1, the registered temperatures were saved on a digital card. To make adjustments, these measurements were first processed and examined using the Arduino® platform IDE's serial monitor. The sensed data were then saved on an SD card as an Excel comma delimited file. The National Meteorological Service – National Water Commission (SMN-CNA) database, which features meteorological station 00019052, San Nicolás de Los Garza,21 provided the historical maximum, minimum, and average temperatures as a point of reference.

The cost of the materials needed to construct the temperature control and registration system was recorded in a table with seven columns: concept, description of the concept, unit of measure, quantity, number of units, unit price, amount, and the percentage that each of these concepts represents of the system's overall investment.

The system's operating expenses were calculated taking into account the two primary variable inputs: energy to run the 0.5 hp (0.373 kW) water pump and gas to heat the water. The amount of energy used will depend on how severe the winter is. An estimate of the expected temperature values was made, followed by an estimate of the energy consumed, using the temperature registers from the SMN-CNA meteorological station 19052 of the World Meteorological Organization Integrated Global Observing System (WIGO) WIGO Station Identifier (WSI) 76393, parallel 25.73361111° meridian -100.3047222°, elevation 515 meters above mean sea level (AMSL).

The species' biological traits were considered when choosing the temperatures during the design process. The lowest temperature that tilapia can withstand is 17°C; the higher the temperature, the better for development; and the intermediate range is when diseases start to show up in recirculating aquaculture systems.

By switching the on/off state of the heat source, the 13.3kW step heater that was chosen generates more energy than is needed to reach the target temperature in the fish tank. This is a necessary prerequisite for putting the suggested control approach into practice. Finally, the length of the heat exchanger was calculated with the following function:

The variables: Ti, Te, hi, he, k1, k2, r1, r2, and r3, can be appreciated in Figure 4.

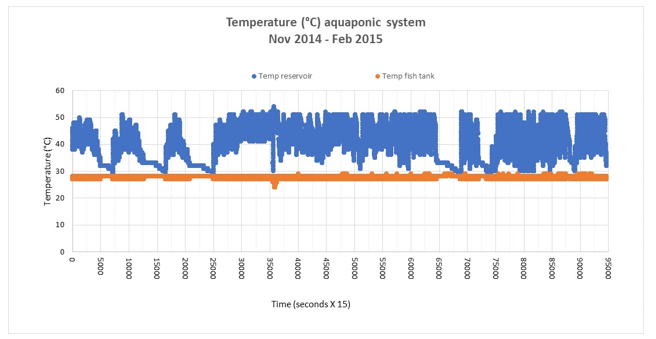

Figure 5 Graph showing the water temperature in the fish tank oscillating between 27 and 28 °C, as programmed. While the water temperature in the reservoir oscillates between 40 and above 50 °C so the cut off signal was reprogrammed to cut off at 40 °C to avoid temperature reaching 50 °C or more.

Water's heat transfer coefficient fluctuates between 50 and 3,000W/m2°K under induced convection and between 50 and 10,000 W/m2°K under natural convection. Since forced convection is at play here, the following information was taken into account while calculating the heat transfer rate per unit length: Inside the tube, the convection-induced heat transfer coefficient, hi, is 10,000 W/m2°K. For the outside tube, there are three values of he: 5,000 W/m2°K, 7,500 W/m2°K, and 10,000 W/m2°K. In contrast, copper's thermal conductivity (k1) is 386 Wm°K, while acrylic's thermal conductivity (k2) for plasticized paint is 0.17 W/m°K. Table 3 summarizes the calculation's result based on these three values for he. It shows that the heat transfer per unit length (q/L) is 5.6 KW/m, and that the proposed 4 m long heat exchanger can dissipate 22.4 KW, which is feasible to meet the 19 KW-H requirements with a 17% margin.

|

Formula |

he |

||

|

5,000 |

7,500 |

10,000 |

|

|

2pi(Ti -Te) |

176 |

176 |

176 |

|

1/(r1hi) |

0.01639 |

0.01093 |

0.00820 |

|

1/k1(ln(r2/r1)) |

0.000082 |

0.000082 |

0.000082 |

|

1/k2(ln(r3/r2)) |

0.009256 |

0.009256 |

0.009256 |

|

1/(r3he) |

0.01515 |

0.01515 |

0.01515 |

|

q/L (KW/m) |

5.6 |

6.7 |

7.5 |

|

q (KW) |

22.25 |

26.90 |

30.03 |

Table 3 Results of the length approximation for the copper tube heat exchanger considering forced convection and three different values for the heat transfer coefficient he

The minimum average temperature in the meteorological station 19052's influence zone during the 2014–2015 winter was 9.74 °C, S = +/- 3.9994, the maximum was 20.75 °C, S = +/- 6.3729, and the average was 15.24 °C, S = 4.5247, which is in contrast to the ideal temperature for the thriving development of the tilapias (Table 4).

|

Temperature winter 2014 - 2015 |

||||

|

Month |

Statistic |

MAX (°C ) |

MIN (°C) |

PROM (°C) |

|

Dec - Jan |

Xaverage |

17.84 |

6.69 |

12.27 |

|

S |

7.00641028 |

2.76489126 |

4.55701633 |

|

|

|

N |

31 |

31 |

31 |

|

Jan - Feb |

Xaverage |

21.78 |

9.82 |

15.80 |

|

S |

6.09222701 |

3.1499407 |

4.02866881 |

|

|

|

N |

31 |

31 |

31 |

|

Feb - Mar |

Xaverage |

22.60 |

10.16 |

16.38 |

|

S |

7.5325239 |

4.1963067 |

5.0953501 |

|

|

|

N |

28 |

28 |

28 |

|

Dec - Mar |

Xaverage |

20.7 |

8.9 |

14.8 |

|

S |

7.13575338 |

3.72016219 |

4.88278732 |

|

|

|

N |

90 |

90 |

90 |

Table 4 Monthly minimum, maximum and average winter temperature 2014 – 2015 period. Made with data from the meteorological station 19052. CNA, San Nicolás de Los Garza, Nuevo León

An Arduino UNO® microcontroller was used to optimize the system's heat consumption. A program was created using the methodology based on the previously indicated assumptions (Appendix A). In addition to recording the time and date, this software allows temperature control.

This design would allow the system to alternately turn on and off the flame at the heat source by turning on and off the water pump that circulates the water in the hydraulic circuit. As a result, the temperature in the fish tank is effectively controlled to fall between 27 and 28 °C, which is the optimum Figure 5.

The necessary heat exchanger investment is broken down per component in Table 5. The system costs $16,056 (sixteen thousand and six pesos), with the unit prices of its components arranged in descending order. The heat source accounts for 41.79% of the overall cost, followed by the electronic register and control unit (16.78%) and the water pump (12.08%), which together account for 70.59% of the system's total cost.

|

|

|

Measuring |

Units |

Unitary price |

Sum |

Sum |

|

Concept |

Concept description |

unit |

(#) |

($/unit) |

($) |

(%) |

|

Heater |

domestic step boiler 13.1 KW |

unit |

1 |

6,700 |

6,700 |

5438.31 |

|

Control unit |

temperatura logger and control unit |

unit |

1 |

2,695 |

2,695 |

2187.50 |

|

Water pump |

0.373 KW centrifugal water pump |

unit |

1 |

1,939 |

1,939 |

1573.86 |

|

Paint |

Plasticized pool paint |

unit |

1 |

776 |

776 |

629.87 |

|

Solder |

plumber solder and paste solder |

unit |

1 |

546 |

546 |

443.18 |

|

Tube |

1" diámetre copper tube |

meter |

4 |

127 |

509 |

413.25 |

|

Tee's |

cpvc Tee 1" diametre |

unit |

7 |

73 |

508 |

412.16 |

|

Xylen |

Solvent to dilute the plasticized paint |

unit |

1 |

432 |

432 |

350.65 |

|

Foot valve |

Valbula check y rejilla de 1" |

unit |

1 |

341 |

341 |

276.64 |

|

Soplete y gas |

propane torch and 1 lb gas tank |

unit |

1 |

311 |

311 |

252.44 |

|

Tubo de cpvc |

cpvc tube 1" de diameter |

meter |

4 |

72 |

288 |

233.67 |

|

Tee de bronce |

Tee de cobre de 1" de diámetro 90 grados |

unit |

4 |

70 |

280 |

227.34 |

|

Tow |

disposable paintor towell |

unit |

1 |

247 |

247 |

200.49 |

|

CPVC elbows |

cpvc 1" diameter |

unit |

5 |

30 |

152 |

123.21 |

|

Paint brush |

general use paint brush 2.5" |

unit |

1 |

132 |

132 |

107.14 |

|

CPVC Adhesive |

high temperature cpvc adhesive |

unit |

1 |

123 |

123 |

100.00 |

|

Copper elbows |

1" diámetre 90° copper elbows |

unit |

2 |

39 |

78 |

63.13 |

|

Total |

|

|

|

|

16,056 |

13033 |

Table 5 Heat exchanger materials listed in descending order as a function of price sum

Three components make up 65.31% of the total cost of the heat exchanger's electronic control and register component: the digital thermometers (12.62%), the relay shield (30.24%), and the SD reader shield (22.45%).

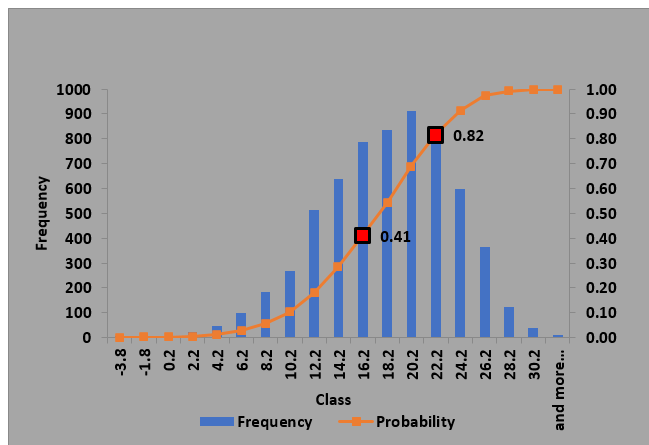

The operation expenses fluctuate as a function of the weather, yet it is possible to establish based on the three scenarios studied, width-modulated amplitude pulses for the time that the recirculating water pump and the heat source will remain turned on. Table 6 & Figure 6 show the outcome of these estimations.

|

Concept |

kW-h |

|

Water heating |

5,596 |

|

Water pump |

157 |

|

Total |

5753 |

Table 6 Energy required to heat water in the fish tank and to operate the .373 kW water pump used to recirculate water in the heat exchanger

Figure 6 Frequency and cumulative probability histogram for average winter temperature by class interval 1951 – 2012, n = 6,288. Elaborated with data from the official meteorological CNA station number 00019052.

Given that one kW-h costs $1.08/kW-h, the heat exchanger's operating expenses come to $6,213 (six thousand two hundred and thirteen pesos).

Even though the hydraulic system was designed to extinguish the flame at 50°C, we observed during the early tests that the recirculating water temperature regularly exceeded this threshold. This can occur because, according to the heat capacity of copper (0.385 j(g°K)-1), there is still a temperature differential and energy left in the copper after the flame has been extinguished. As a result, the system's recirculating water continues to be heated.15,16

To prevent damage or an early deterioration of this equipment, the water pump manufacturer's requirements state that the maximum operating temperature should be 50°C or below. In light of the aforementioned, it was determined to change the program so that the cutoff flame temperature is 40°C. This allows the equipment to operate adequately and transfers the mining energy in the copper, optimizing the process.

Le et al.22 presented a similar hydraulic heating system that uses 34 meters of stainless steel tubing arranged in a spiral pattern along the cylindrical fish tank's wall.

However, a high-temperature circular sector of water is created nearby alongside the breath of the cylindrical wall of 5.88 m2, increasing heat loss, because the circulating water flow lines do not cross and are deflected by friction to the central drain when they reach the bottom of the tank23. In contrast, the proposed system uses less materials, 4 meters of copper tube, installed away from the walls and at the opposite side of the fish tank discharge, this geometry maximizes heat transfer to the water in the fish tank by mixing water at lower temperature with water at higher temperature.

Otherwise, the date and time that correlate to the temperatures were not part of the control system's original design. The former, as it is not necessary for the system to operate successfully and efficiently.

Furthermore, we could see that nighttime, after sunset, and right before morning were typically the times with the lowest temperatures.21 However, in order to make the system more environmentally friendly while maintaining maximum productivity, a real-time clock was later added because it is inexpensive and practical for conducting proper system monitoring and analyzing potential improvements, like adding a water solar heating source or another renewable energy source.22,24,25

In this way, one of the software programs that are on the market can be used to create a customized control power interphase unit. While some of these, like Eagle,26 permit the free use of the software for modules smaller than specific dimensions, others, like KiCad, are free, have no limitations on the size of the PCB, and can be designed in multiple layers (KiCad.org Home Discover in pcbNew.27

Following PCB design, there are a number of options: 1) Using one of the numerous variations of the serigraphy technique, print the circuit's mirror image on photography-quality paper using a laser printer, then transfer it to a universal phenolic plate. 2) Produce the Gerber files and forward them to one of the several businesses in the industry. The customer can then either print the PCB alone and assemble the components, or the firm can print and assemble the components.26

Businesses that specialize in printing and assembling parts offer competitive pricing and high-quality products; for instance, ten plates on two layers cost $5 USD, or $0.50 each plate. Regarding delivery time, there is also the option of a 24-hour window.28 By employing only the necessary components, expenses can be decreased in this way. Only two of the four ports on the module used to manage electricity in this project are really in use.

A control system can be designed and implemented in a wide range of ways for both industrial and residential purposes. According to Lahfaoui et al.,19 most scientific papers discuss how to simulate Maximum Power Point Tracking (MPPT) to create more efficient wind turbines, but in reality, the real difficulty lies in implementing the simulation in an electronic card. Because of this, the authors decided to utilize an Arduino UNO connected to a PC, a direct current to direct current converter (DC-DC), and an optocoupler to control the wind turbine's permanent magnet synchronous generator (PMSG). Because of its effectiveness, affordability, and user-friendliness, they are able to efficiently achieve the wind turbine's optimal working. Similarly, Naveenkumar and Krishna29 created a framework that uses LabView and the Arduino platform to create low-cost prototypes for control and data collecting.

In their investigation, they highlight how rigid and unadaptable the conventional mechanisms used in the sector for data collection and monitoring are. They are also able to exhibit some of the features of the suggested system, including its low cost, user-friendliness, and numerous applications for data recompilation and monitoring in the lab and industry.

Louis20 describes the fundamentals of the Arduino Uno microcontroller's operation and how it is used in research and study-related activities. highlights that this platform was created to meet the demands of professionals, students, and hobbyists who want to create inexpensive devices that use sensors and actuators to interact with their surroundings. The study highlights that, in addition to being inexpensive, the technology is very dependable and provides a succinct explanation of its features and range of potential applications.

The creation of artificial intelligence-based solutions is at the other extreme of the automation and control spectrum. Three major types are mentioned by Lee14: The most important considerations when choosing a solution are 1) knowledge-based expert systems, 2) fuzzy logic-based expert systems, and 3) neural networks and hybrid systems. The most important considerations are cost and software and hardware compatibility.

Regarding this, the ESP32 microcontroller has a higher capacity, is compatible with the Arduino integrated development environment, and offers a low-cost option with a lot of versatility. Programmable in C, C++, and micro Python, it features an LX6 dual core processor, 512 KB of RAM, 36 general input/output ports, Bluetooth, WiFi (2.5Gb), and a 3.3V power supply (ESPRESSIF Hardware Product Overview DevKits Esp32-S series).30

Recirculating aquaculture systems (RAS) are known for their ability to reduce their impact on land and water use, but they also result in increased energy consumption, which raises production costs and has an adverse effect on the environment. For this reason, efforts to optimize the design should take into account four factors: energy, water, discharges, and productivity, always keeping in mind that fossil fuels are less environmentally friendly than renewable energy sources.31

Nonetheless, hybrid energy sources are required to meet the energy requirements of RAS and aquaponics, and controlling the ideal ratio that these systems employ becomes the only challenge.32 Numerous tactics have been employed to achieve this, including the coupling of separate systems to maximize the utilization of energy, water, and nutrients. These systems can separate the ingredients needed to produce fish and plants. The water high in nutrients from the fish is transferred to the plants as fertilizer, while the evapotranspiration from the plants, free of nutrients, is condensed and returned to the fish tank.24

Regardless of its source, the current idea for a temperature-controlling system for tilapia farming in northeast Mexico can improve energy efficiency. Additionally, the ArduinoUNO is regarded as the first option among the many and expanding platforms because of its support, cost, dependability, energy consumption, general input/output pin (GPIO) output current, startup time, and learning curve.33

The Gamma distribution is parameterized in this paper in terms of the mean and the standard deviation. The probability density function of a Gamma distributed variable x is

The authors thank Fundación Produce and PAICYT for the sponsorship provided.

AAG thanks the Mexican Secretariat of Science, Humanities, Technology, and Innovation (SECIHTI) for the doctoral scholarship provided.

We declare that there is no conflict of interest of any kind. The research was done with a clear purpose in mind to discern what the state of the art has to offer and to contribute to its development.

©2025 Gámez, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.