The scheme of the piezoengine with lumped parameters has big interes in calculation nano mechatronics systems for aerospace. The scheme of the piezoengine is determined from the equation of the reverse piezoeffect and the equations forces of engine in dynamics by using method mathematical physics.11–64

The equation reverse piezoeffect has the form1–64

(1)

Here the indexes i, j, m and

,

,

,

,

are the relative displacement, the strength electric field, the strength mechanical field, the piezo module, and the elastic compliance at

.

Therefore, we have the Laplace transform general force46–62 at voltage control

of the nano piezoengine in the form

(2)

Also we receive the Laplace transform general force at voltage control from the voltage

on its piezo capacitor

(3)

Than this Laplace transform general force of the piezoengine is obtained

(4)

Here

is the reverse coefficient in the form

(5)

The equation direct piezo effect 1-64 has the form

(6)

Here

,

are the permittivity, index

Than the direct coefficient

at voltage control is founded in the form

(7)

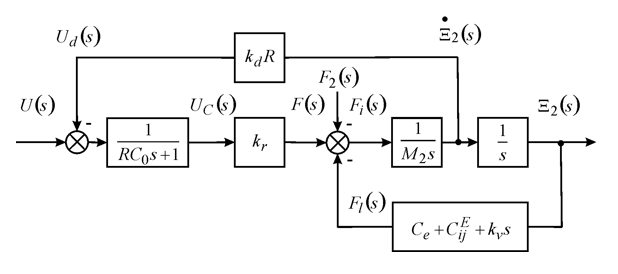

Therefore, we have the Laplace transform voltage

for the feedback on the velocity of the second end at voltage control on Figure 1 in the form

(8)

Here

is the Laplace transform velocity the second end of the nano piezoengine.

The Laplace transform force at the second end

of the nano piezoengine and the load force are used (Figure 1). The transform force for the feedback on the load force at voltage control is obtained in the form

(9)

Here

,

,

are the elastic load stiffness, the stiffness piezoengine at ,

the coefficient of viscous friction.

This Laplace transform the load force is founded in the form the sum of the elastic force and the viscous friction force.

The scheme for lumped parameters of the nano piezoengine (Figure 1) at voltage control is constructed for the first fixed end, the elastic inertial load with the mass load

. The inertia force

has form

(10)

Here

is the Laplace transform displacement the second end of the nano piezoengine.

Let us consider transformation transfer function for scheme (Figure 1) at

about several Om. Than for no the feedback on the velocity the Laplace transform equation for forces on the second end of the piezoengine has the form

(11)

The transfer function of the nano piezoengine has the form

(12)

And

(13)

By using the feedback on the velocity

after conversion transfer function of the nano piezoengine) at more 100 Om we have the transfer function in general for lumped parameters of the nano piezoengine for voltage control (Figure 1) in the form

(14)

,

(15)

,

(16)

Figure 1 Scheme piezoengine for lumped parameters at voltage control.

Than the transfer function of the nano piezoengine at voltage control for

is founded in the form

(17)

(18)

,

(19)

For PZT engine

= 0.2∙nm/V,

= 20,

= 0.5×107 N/m,

= 1.1×107 N/m its transfer coefficient at voltage control is determined

= 2.75 nm/V with error of 10%. For PZT engine

= 1 kg,

= 0.5×107 N/m,

= 1.1×107 N/m its time const at voltage control is obtained

= 0.25×10-3 s with error of 10%.

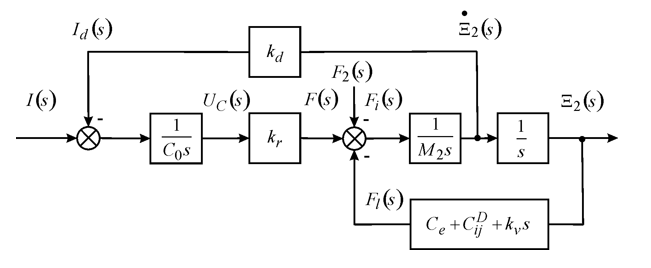

For direct feed of the nano piezoengine at current control we have the transform general force by using the voltage

on the piezo capacitor in the form

(20)

Here

,

re the current, the the elastic compliance at

The Laplace transform current

for the feedback on the velocity the second end of the piezoengine is founded at current control on Figure 2 in the form

(21)

The direct coefficient at current control

is founded

(22)

The Laplace transform load force

for the feedback at current control has the form

(23)

The scheme for lumped parameters of the piezoengine at the current control is constructed (Figure 2) at the first fixed end, the elastic inertial load.

Figure 2 Scheme piezoengine for lumped parameters at current control.

The schemes of the piezoengine for lumped parameters at the voltage or current control are used in calculation nano mechatronics systems for aerospace. Let us consider parameters of the piezoengine for lumped parameters at the current control in static regime.

(24)

After conversion we have equation in the form

(25)

,

(26)

Here

is the electromechanical coupling coefficient. The elastic compliance of PZT engines was measured using the UMM-5 press

with error of 10%.